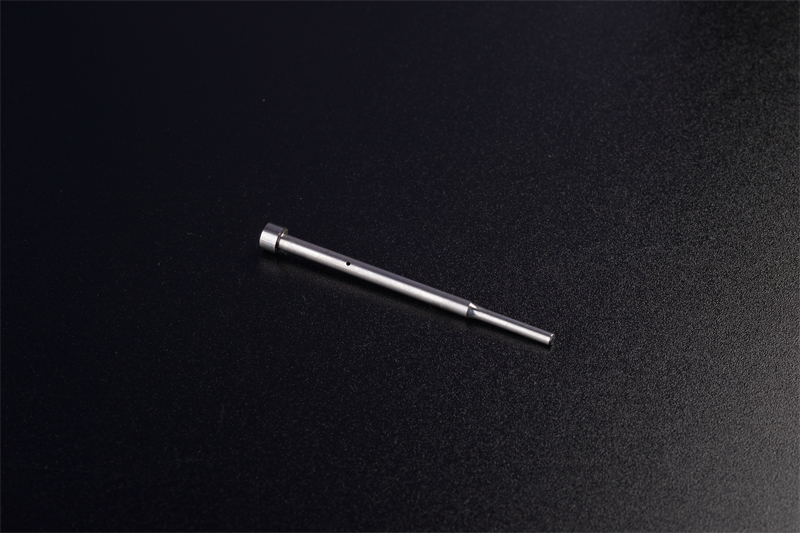

Centerless grinding of punching needle mold

Get Latest Price| Payment Type: | Paypal,Others |

| Transportation: | Ocean |

| Payment Type: | Paypal,Others |

| Transportation: | Ocean |

Brand: yushun

Place Of Origin: China

| Selling Units | : | Piece/Pieces |

Centerless grinding is a machining process that involves the use of abrasive cutting to remove material from a workpiece without the need for a center or spindle. In the case of punching needle molds, centerless grinding can be used to achieve precise and consistent diameter tolerances on the needles.

To perform centerless grinding on a Punching Needle Mold, the mold is first mounted on a workpiece rest blade and a regulating wheel is positioned opposite the workpiece. The regulating wheel rotates at a slower speed than the grinding wheel, which is positioned above the workpiece.

As the grinding wheel spins, it removes material from the workpiece by means of the abrasive particles embedded in its surface. The regulating wheel controls the rotation speed of the workpiece, ensuring that it moves smoothly through the grinding process.

During the grinding process, coolant may be applied to the workpiece to prevent overheating and to wash away any debris generated by the grinding process. Once the desired diameter tolerance has been achieved, the workpiece can be removed from the machine and subjected to any necessary finishing processes before being used to produce punching needles.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.