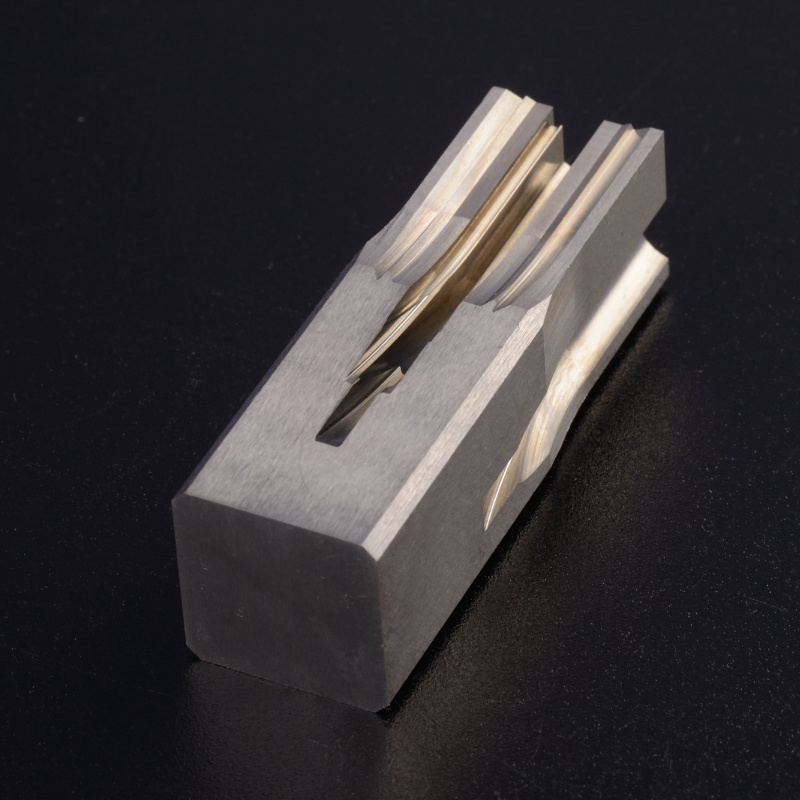

Professional slow wire processing manufacturer - ultra-precision parts processing

Professional processing of various molds and parts

Among many precision machining technologies, slow

Wire cutting plays an important role in the field of high value-added parts processing due to its excellent machining accuracy. Its development has grown by leaps and bounds in recent years.

Slow wire cutting is a type of wire EDM. It uses a continuously moving thin metal wire (called an electrode wire) as an electrode to perform pulse spark discharge on the workpiece to erode the metal and cut into shape. It is mainly used to process various workpieces with complex shapes and precision.

Slow wire cutting, also called low-speed wire walking, is a common precision parts processing method. It uses a continuously moving thin metal wire (called an electrode wire) as an electrode to perform pulse spark discharge on the workpiece to remove metal and cut into shape.

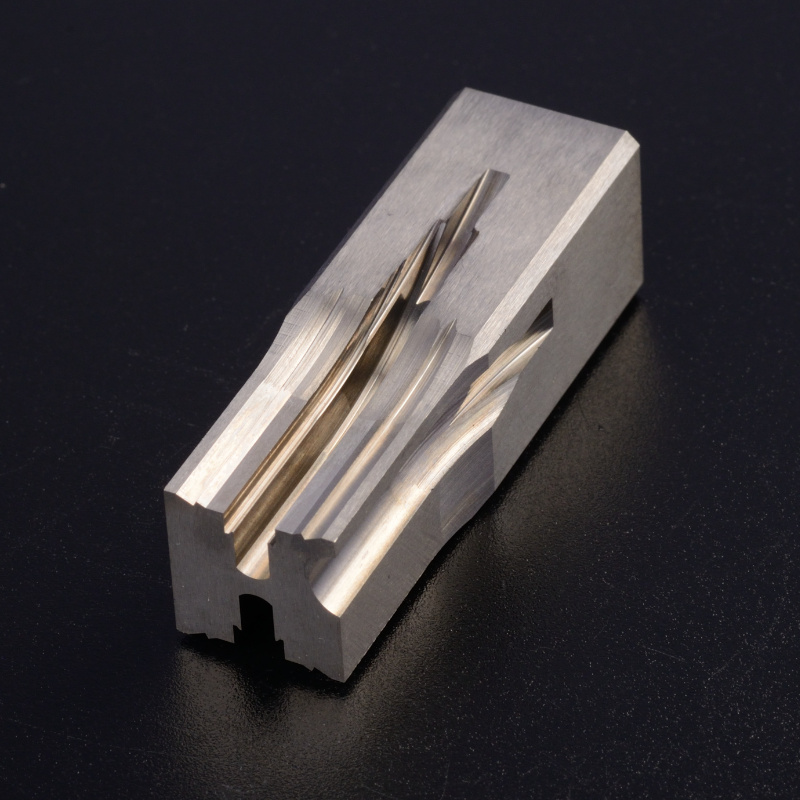

Nowadays, slow wire processing has reached an amazing level of precision. The dimensional accuracy can be controlled within 1 μm, precise positioning can achieve nanoscale equivalent control, and the surface roughness index can reach within Ra0.05 μm.

Slow wire cutting is mainly used to process various complex-shaped and precise fine workpieces, and can be used to process various types of metal materials, such as steel, copper, aluminum, etc. In addition, it can also be used to process some non-metallic materials, such as plastics, ceramics, etc. Slow wire machining can achieve highly precise machining and achieve high surface quality requirements.

The current leading slow wire processing accuracy indicators: dimensional accuracy can be controlled within 1μm; true roundness is less than 0.8μm; precise positioning can achieve nano-level equivalent control, and the step accuracy within 100mm can reach ±0.5μm, even if It can also achieve a step accuracy of ±1μm when processing the full stroke range of a 500mm large template; the lead frame cutting contour shape accuracy can reach ±0.5μm; and a tiny internal angle of 0.02mm can be processed. (1 micron μm = 0.001 mm mm)

Slow wire cutting processing is mainly used for processing two-dimensional and three-dimensional ruled surface parts such as various punch dies, plastic molds, powder metallurgy molds, etc. Among them, the processing of stamping dies accounts for the largest proportion. For the processing of many precision holes such as the punch, punch fixed plate, concave die and discharge plate of the stamping die, slow wire cutting processing is an indispensable key technology. In injection mold manufacturing, common applications include insert holes, ejector holes, inclined top holes, cavity corners and slider processing.