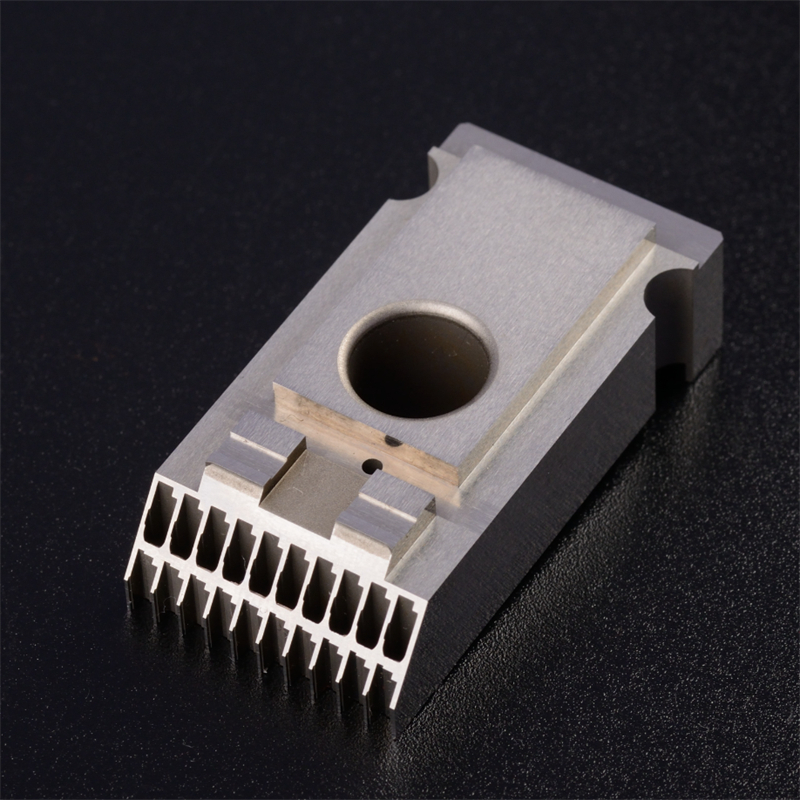

Custom metal stamping dies parts

Get Latest Price| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean |

Brand: yushunmould

Place Of Origin: China

Technology: Metal forming

Quality Grade: optimal

Specification: On-demand customization

Model Number: Support non-standard customization

Process Type: Stamping die, CNC slow wire cutting

Quantity: Can be produced on demand

| Selling Units | : | Piece/Pieces |

Professional custom metal stamping dies | metal stamping die manufacturer

Efficient Metal Stamping and Custom Mold Manufacturing

Metal stamping and mold manufacturing are a perfect pair in the manufacturing industry, providing efficient and precise solutions for production. In this field, Yushun Precision Mold Co., LTD stands out in production with its unique craftsmanship.

Metal stamping is a widely used rapid and efficient manufacturing method that can produce standard, custom, and complex stamped parts. Yushun Precision Mold Co., LTD ensures the quality and traceability of each stamping job with its highly integrated production facilities. Batch numbers and quality control documents accompany each job, while routine inspections are an essential part of ensuring product quality.

I. Concept of Stamping Mold

Stamping molds, also known as dies, metal molds, or metal stamping molds, all refer to the same thing. It is a method of pressure processing that applies a certain pressure to metal or non-metal sheets fixed on a press or press to achieve separation or forming of materials and obtain pressure-processed parts with specified size requirements and qualified appearance. There are many types of molds, and here I mainly focus on the metal stamping molds I am familiar with. Products processed by molds are generally similar in size and appearance, with little difference. They can be quickly formed, have high production efficiency, stable product quality, meet the required precision, and have high material utilization.

II. Introduction to the Structure of Stamping Mold

The structure of stamping molds, die structures, mold structures are similar, and different molds have different functions, and the products produced are different. However, regardless of the complexity of the structure, its basic structure remains the same and mainly consists of several templates, units, and standard parts.

Molds are usually assembled from several templates and components (referred to as units or dies) as well as standard parts. The typical structure of stamping molds, specific templates from top to bottom (including code numbers) include: upper mold templates such as upper bolster, upper pad, upper punch unit (UPU), upper bolster unit (UBU), upper clamp plate (PHU), stop plate (PPS), stripping plate (PSU); lower mold templates include lower die (DIE), lower bolster (LBD), lower die unit (LPD), lower pad, lower bolster plate; other less commonly used templates include upper cover plate (CVU), knockout plate, upper punch plate, lower strip plate, lower stop plate, lower clamp plate, male mold, female mold, etc.; some mold components include upper die units, inserts: clamp inserts, stripping plate inserts, punches, etc.; lower die units, inserts: lower die inserts, lower die cutters, etc.; standard parts: springs, hex screws, stop screws, coil springs, guide pins, guide sleeves, spacer rings, double-ended pins, material stop pins, etc.; custom parts: external positioning, internal positioning, pitch positioning, external limit posts, internal limit posts, etc.

The manufacturing process of stamping molds includes design, processing, assembly, commissioning, and maintenance steps. In modern mold manufacturing, advanced technologies such as cnc machining, EDM, and laser cutting are widely used to improve the manufacturing accuracy and efficiency of molds.

Before manufacturing stamping molds, detailed design work is necessary. This includes determining the type, structure, size, and working principle of the mold. The design phase typically uses Computer-Aided Design (CAD) software to create a three-dimensional model of the mold and conduct simulation analysis to ensure the feasibility and efficiency of the design.

Choosing the appropriate mold material is crucial. Common mold materials include high-speed steel (HSS), powdered metallurgy steel, hard alloy, and tungsten steel. The choice of material depends on the intended use of the mold, the properties of the stamping material, the stamping speed, and the expected lifespan of the mold.

The manufacturing process of stamping molds typically includes the following steps:

*Cutting and Pre-processing: Cut the selected mold material into rough shapes and conduct preliminary processing such as milling, turning, etc.

*CNC Machining: Precision machining of the mold using CNC machine tools includes drilling, milling, grinding, etc.

*Electric Discharge Machining (EDM): For complex shapes and fine holes, EDM may be required to complete.

*Wire EDM Machining: Wire cutting technology may be used for extremely fine cutting.

*Heat Treatment: To improve the hardness and wear resistance of the mold, heat treatment such as quenching and tempering is usually required.

*Surface Treatment: Surface hardening, coating, or other surface treatments may be applied to reduce wear and improve corrosion resistance.

After the various components of the mold are processed, accurate assembly is required. During the assembly process, it is essential to ensure that all components are correctly installed, and the moving parts of the mold can operate smoothly. After assembly, the mold needs to be commissioned to ensure it works properly during actual stamping processes.

After the assembly and commissioning of the mold are completed, trial stamping will be conducted to check the performance of the mold and whether the products meet the design requirements. If any issues are found, adjustments and optimizations may be necessary.

Regular maintenance and care are required for stamping molds during use to maintain optimum performance. This includes cleaning the mold, checking for wear, replacing damaged parts, etc.

From the above information, we can understand the importance of metal stamping and custom mold manufacturing and the key steps in the manufacturing process. Yushun Precision Mold Co., LTD provides high-quality Precision Die and Stamping to customers with its efficient production facilities and strict quality control. Feel free to contact us.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.