Electrical discharge machining (EDM) Basic Principles

The principle of electrical discharge machining is based on the phenomenon of electrochemical erosion during pulsed spark discharge between the tool and the workpiece (positive and negative electrodes), to remove excess metal, achieving the predetermined machining requirements for the size, shape, and surface quality of the workpiece.

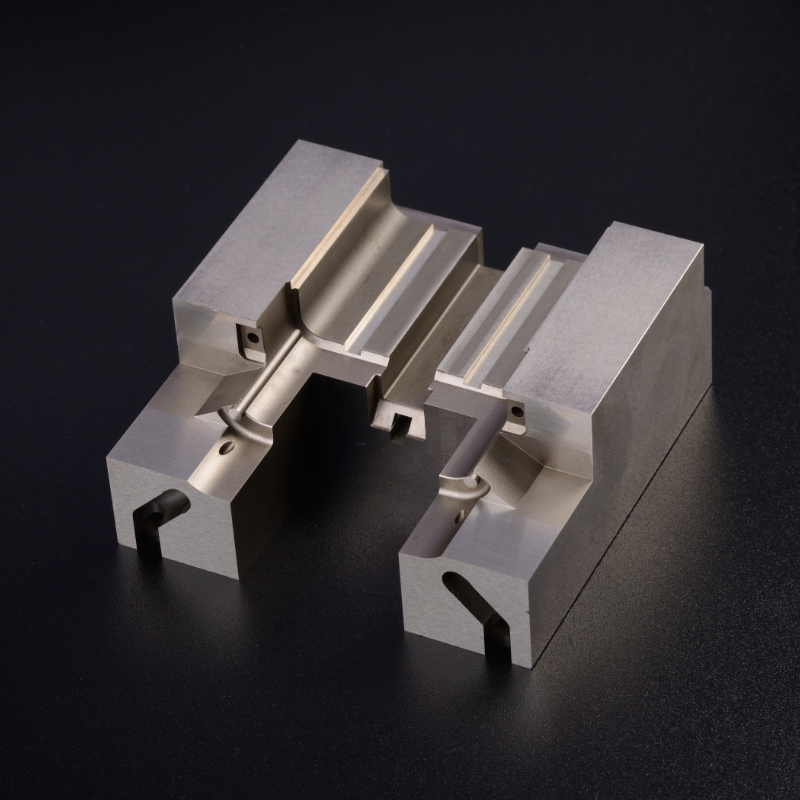

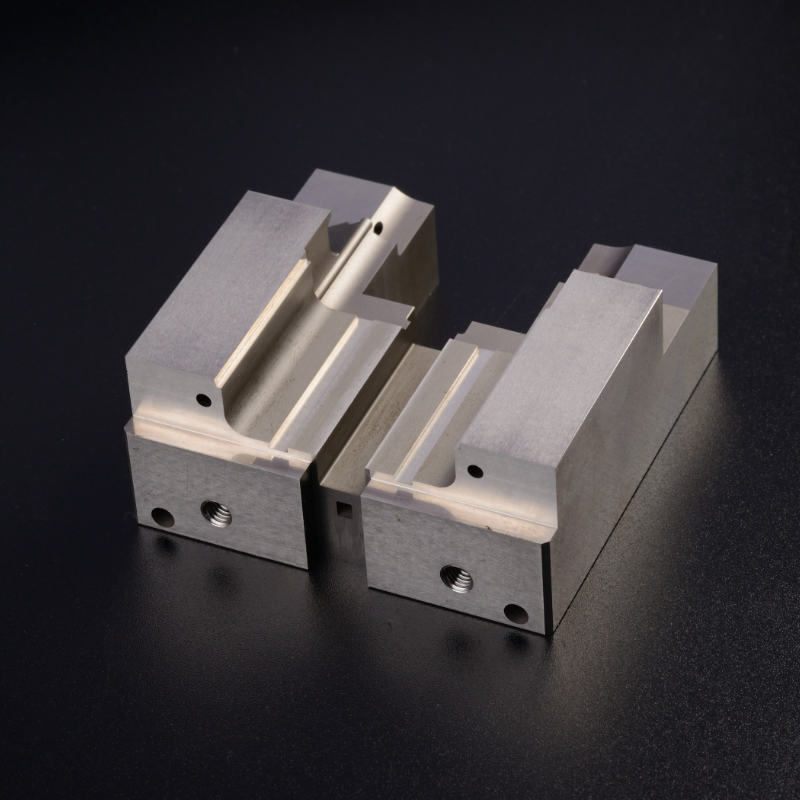

Electrical wire EDM Machining is divided into slow wire and fast wire methods, typically using electrodes with diameters of 0.1 to 0.3mm to machine through-pass straight-lined parts, which can be convex or concave mold parts.

Wire cutting machining doesn’t actually use a thin wire to directly cut metal. In fact, this thin wire never directly contacts the workpiece. Its machining process can be divided into three stages:

Stage One:

An arc is formed between the electrode and the workpiece. A thin and conductive metal wire is used as the electrode, with a very small distance between the electrode and the workpiece, but no direct physical contact. An arc discharge is formed by applying high voltage.

Stage Two:

The arc generates a high-temperature and high-pressure area. The energy generated by the arc discharge is very high, causing the metal on the surface of the workpiece to heat up to a high temperature in an instant. This high-temperature and high-pressure area can cause the metal surface to evaporate and corrode.

Stage Three:

Metal corrosion and removal. In the high-temperature and high-pressure area, the metal begins to corrode and dissolve. The corroded metal particles are washed away by the shock wave, thereby achieving the removal of the metal workpiece. The arc continuously moves between the electrode and the workpiece, allowing the entire cutting process to form the desired shape on the metal surface.

What are the Advantages of Electrical discharge machining Compared to Traditional Machining Methods?

Electrical discharge machining can process any conductive material, including those hard metals that traditional methods cannot process.

Using Electrical discharge machining, it is possible to achieve depths that are impossible with cutting tools. For applications requiring high-depth machining, this is an ideal machining method.

Electrical discharge machining does not apply additional mechanical force to the workpiece during the machining process, ensuring the mechanical properties of the workpiece. Additionally, the surface finish after edm wire cutting is usually better than traditional methods.