We specialize in processing

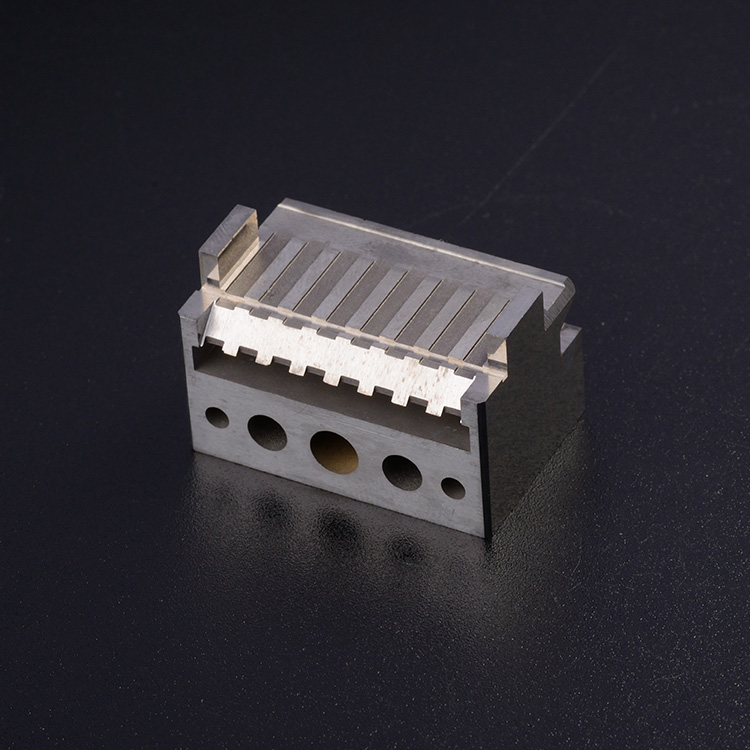

custom metal stamping dies, mold parts, precision parts, etc., and can make them based on drawings or samples with an accuracy of 0.001mm-0.005mm.

Advantages and highlights of our mold parts production

►Meet the needs of customers for large-scale production

►Easy product design process arrangement

When designing molds, we decompose them into precise and simple structures based on product requirements, arranging them in different workstations to avoid fragile parts of the mold structure and increase lifespan, which can reach over 500,000 strokes.

►High product accuracy

From edge cutting to bending forming and blanking, all completed by a set of molds.

►Durable

Using professional materials, the mold lifespan is more than 3 times that of ordinary materials, saving costs for you.

►Precise tolerances

Product tolerances reach ±0.002um, rigorously creating high-quality products.

►High-quality materials

According to the mold material and thickness, different impact-resistant and wear-resistant materials are used.

Precision metal stamping mold parts processing methods: precision flat grinding (tolerance ±0.002), precision

Wire EDM Machining (tolerance ±0.002), precision EDM (tolerance ±0.01), precision optical grinding PG processing (tolerance ±0.002)

Materials: G5, KD20, KX01, CD650, KN20, H40S, ASP23, HAP40, etc.

Appearance and precision requirements of metal stamping molds

The appearance of metal stamping molds should be neat and free of obvious defects such as burrs, cracks, deformation, etc., maintaining flatness and smoothness without obvious scratches and unevenness.

The precision of the mold needs to be high, mainly reflected in the precision of the mold processing technology and the precision of the press, which will also affect the product’s precision.

The professional level of mold makers also affects the mold’s one-pass rate. Many key dimensions of precision molds do not allow slopes, but in mold production, tolerance bands are often utilized to introduce very small slopes, such as gear mounting pillars. When establishing digital models, attention must be paid to tolerance adjustments, as the 3D models provided by customers are often unusable due to using extreme dimensions, leading to potentially scrapping the mold.

We have a professional team for mold parts processing with over 10 years of experience, continuously solving various technical problems, and successfully providing technical solutions and precision parts to over 5000 mold users!