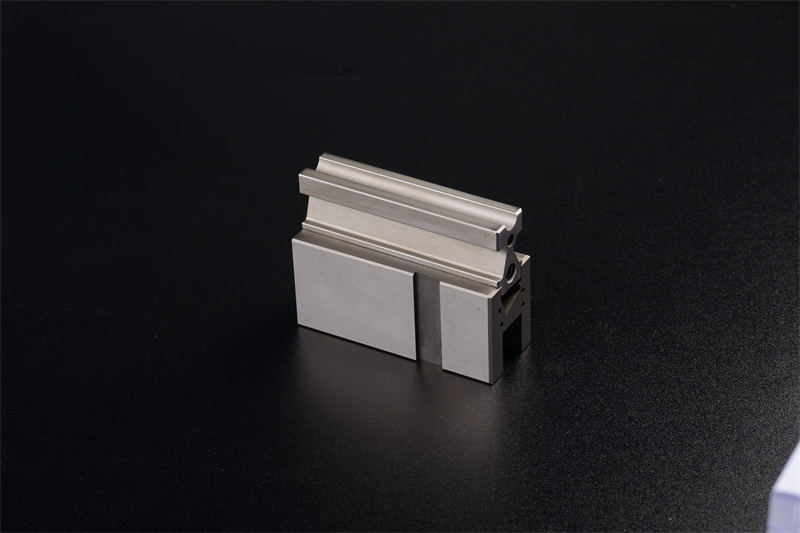

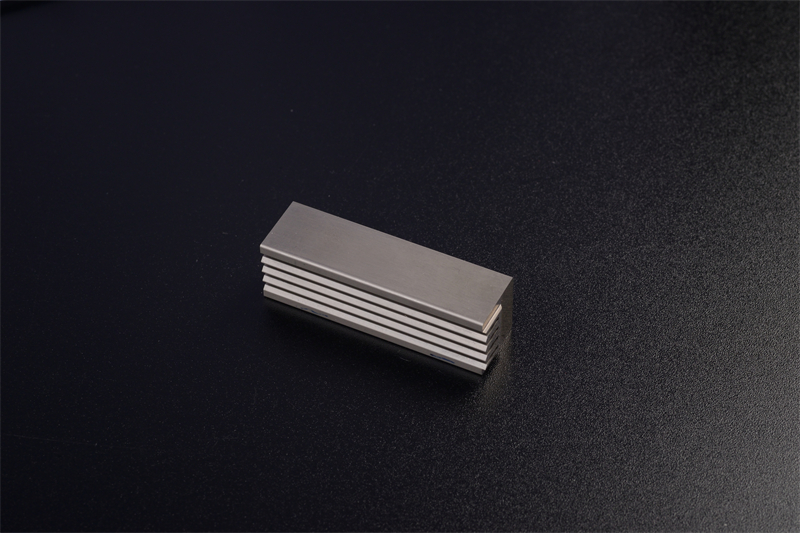

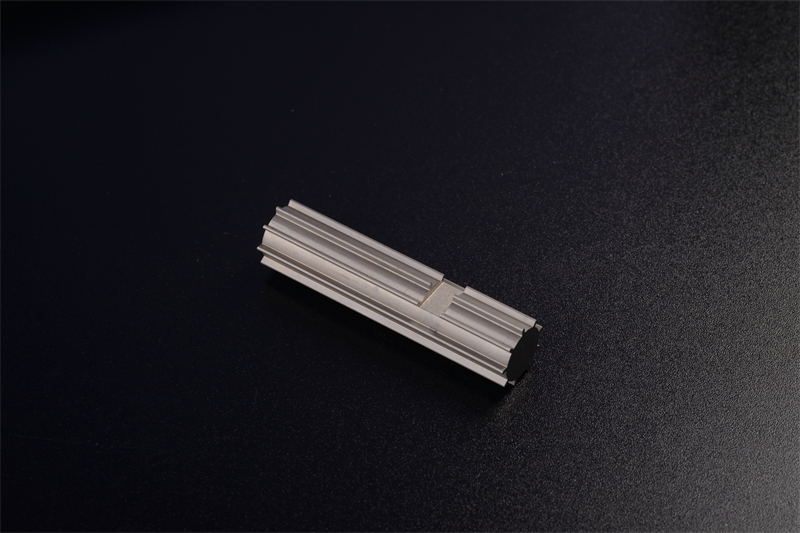

Precision tungsten steel punches and pins

Get Latest Price| Payment Type: | Paypal,Others |

Model No.: ys05

Brand: yushun

Place Of Origin: China

Production Process: grinding

| Selling Units | : | Piece/Pieces |

Precision Metal Stamping Moulds

Wire cutting process is a manufacturing process used to cut or shape materials using a wire EDM machine. This process is commonly used in the mold and die industry to create intricate shapes and contours in molds and dies.

10. The completed mold pin is ready to be used in the injection molding process.

Precision Metal Stamping Moulds display

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.