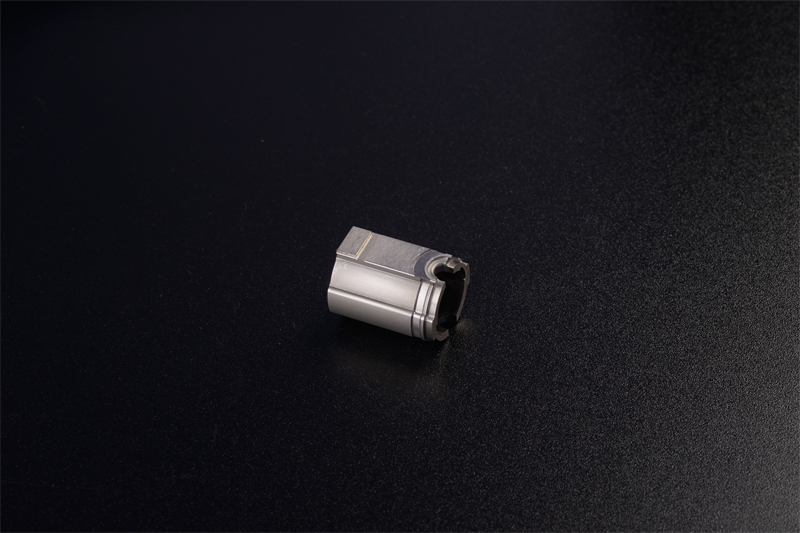

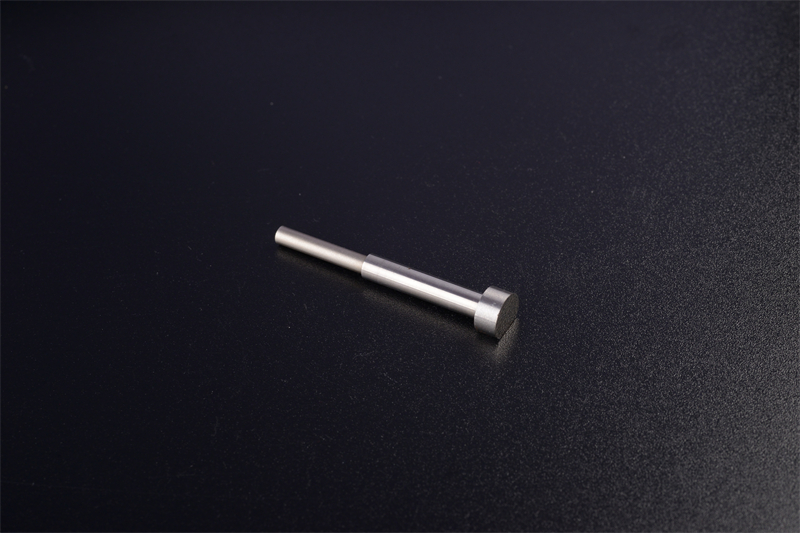

Precision hardware mold processing

Get Latest Price| Payment Type: | Paypal,Others |

| Transportation: | Ocean |

Brand: yushun

Place Of Origin: China

| Selling Units | : | Piece/Pieces |

Precision Hardware Mold Processing refers to the manufacturing of molds that are used in the production of precision hardware parts. The process involves designing and creating a mold that can accurately and efficiently produce a specific part or product.

The first step in precision hardware mold processing is to design the mold using computer-aided design (CAD) software. This allows the designer to create a detailed 3D model of the mold, which can be used to simulate the manufacturing process and identify any potential issues before the mold is actually built.

Once the mold design is finalized, the next step is to manufacture the mold itself. This typically involves using CNC machines to cut and shape the mold from high-quality materials such as steel or aluminum.

After the mold has been completed, it can be used to produce precision hardware parts through processes such as injection molding or die casting. These processes involve injecting molten metal or plastic into the mold cavity, where it cools and solidifies to form the final part.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.