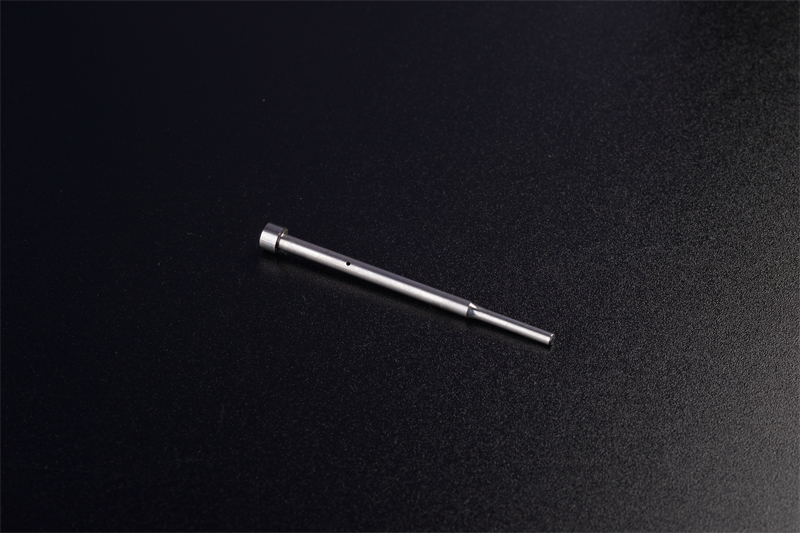

Centerless Grinding of Cemented Carbide Parts

Get Latest Price| Payment Type: | Paypal,Others |

| Transportation: | Ocean |

| Payment Type: | Paypal,Others |

| Transportation: | Ocean |

Brand: yushun

Place Of Origin: China

| Selling Units | : | Piece/Pieces |

Centerless grinding is a common machining process used for producing cylindrical parts with high dimensional accuracy and surface finish. Cemented carbide is a popular material for manufacturing cutting tools, wear parts, and other mechanical components due to its exceptional hardness, wear resistance, and toughness.

In centerless grinding of cemented carbide parts, the workpiece is supported between a regulating wheel and a grinding wheel. The regulating wheel rotates at a slower speed than the grinding wheel and controls the rotational speed and feed rate of the workpiece. The grinding wheel removes material from the workpiece by cutting and abrasion, resulting in a precise and consistent diameter and surface finish of the part.

Cemented carbide parts can be challenging to grind due to their high hardness and toughness. To achieve optimal results, it is necessary to select the appropriate grinding wheel, grinding parameters, and coolant to ensure efficient material removal and minimal thermal damage to the workpiece.

Additionally, post-grinding processes such as polishing or surface treatment may be required to achieve the desired surface finish and functional properties of the cemented carbide part.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.