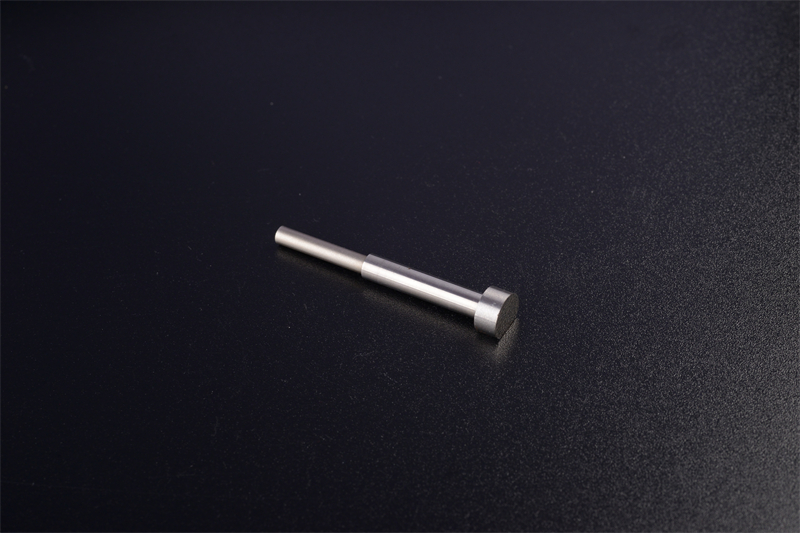

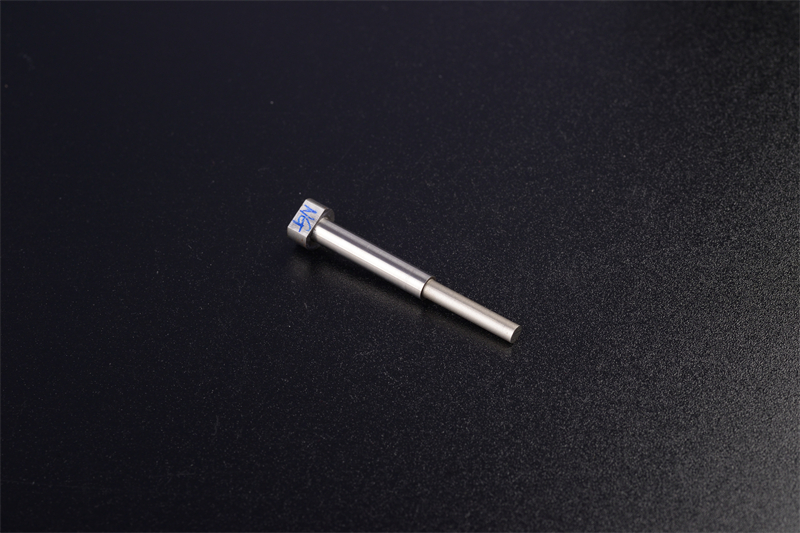

Centerless grinding of precision mechanical parts

Get Latest Price| Payment Type: | Paypal,Others |

| Transportation: | Ocean |

| Payment Type: | Paypal,Others |

| Transportation: | Ocean |

Brand: yushun

Place Of Origin: China

| Selling Units | : | Piece/Pieces |

Centerless grinding is a machining process used to remove material from the outside diameter of a cylindrical part without using centers for support. This allows for high precision grinding of parts with complex shapes and tight tolerances.

In centerless grinding, the workpiece is placed between two wheels: the grinding wheel, which is rotating in one direction, and the regulating wheel, which is rotating in the opposite direction. The grinding wheel removes material from the workpiece by traversing it along the axis of the part, while the regulating wheel controls the rotational speed of the workpiece and the feed rate of the grinding wheel.

The key advantage of centerless grinding is its ability to produce very precise roundness and dimensional tolerances on cylindrical parts. This is achieved through the use of a highly accurate and rigid machine setup, as well as close control over the grinding process parameters.

Some common applications of centerless grinding include the production of bearing components, shafts, valves, pins, and other precision mechanical parts.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.