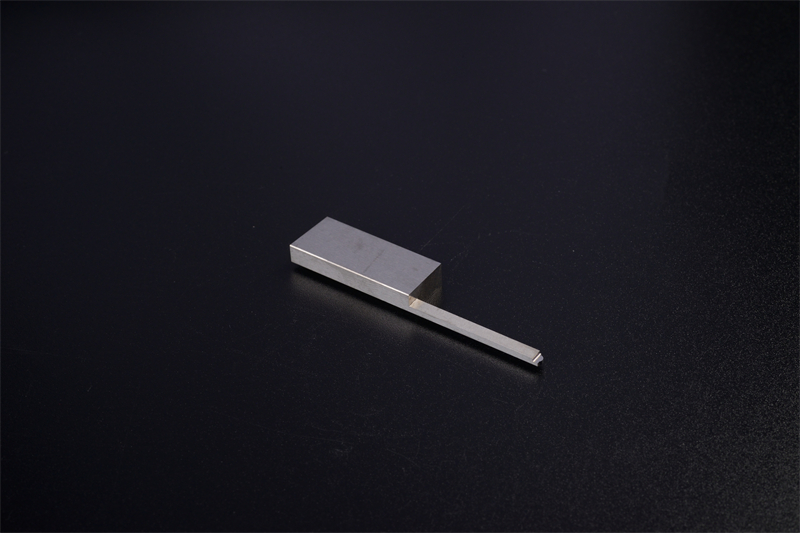

Centerless grinding of precision mold parts

Get Latest Price| Payment Type: | Paypal,Others |

| Transportation: | Ocean |

| Payment Type: | Paypal,Others |

| Transportation: | Ocean |

Brand: yushun

Place Of Origin: China

| Selling Units | : | Piece/Pieces |

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. It differs from centered grinding in that there is no spindle or fixture used to locate and secure the workpiece. Instead, the workpiece is secured between two rotary grinding wheels, which spin at high speeds.

When it comes to precision mold parts, centerless grinding can be an effective way to achieve tight tolerances and a smooth surface finish. This is because the process can remove very small amounts of material from the workpiece at a time, allowing for precise control over the final dimensions and surface quality.

One challenge with centerless grinding of precision mold parts is maintaining consistency in the grinding process. This requires careful attention to the setup of the grinding machine, as well as the selection and dressing of the grinding wheels. It's also important to monitor the grinding process closely, and make adjustments as necessary to ensure that the final product meets the required specifications.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.