Custom nonstandard parts, we strict follow your drawings to produce parts so it can perfect fit your machine, all the parts accuracy can roughness

Plastic mould, precision design and processing connector mould for electronic products, but we can produce other plastic mould also.

We provide customized

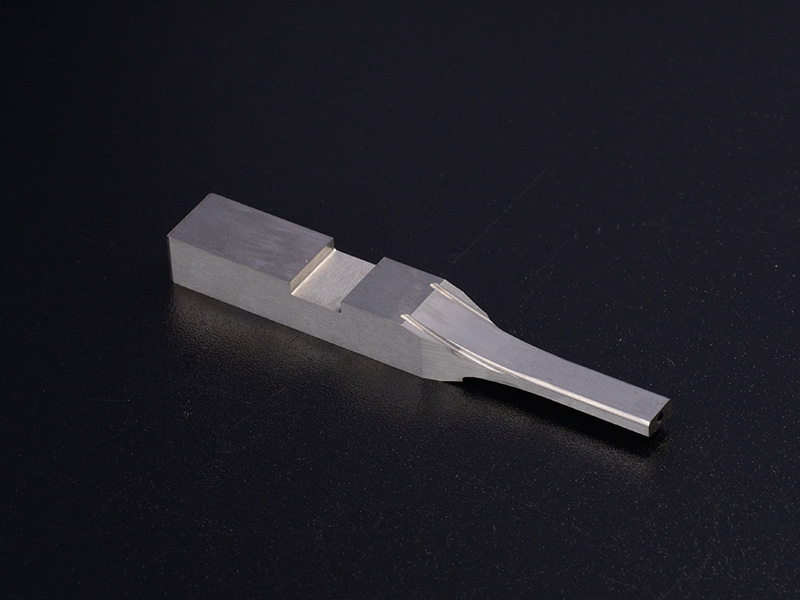

Precision Stamping Mould punch and die spare parts for client, this super precision part processed by wire-cut, Grinding, Jig grinding and so on.

Parts materials include G5,KD20,KX01,CD650,KN20,H40S,ASP23,HAP40 etc., the highest accuracy of 0.005.

Customized Carbide Mould Punches

Carbide Punches ,also known as

Carbide mold components ,are crucial components within molds used for shaping the inner surfaces of molded products. They are precision mold parts crafted from finely ground hard alloy rods, known for their high precision, hardness, and excellent resistance to bending.

Classification and Applications of Carbide Punches

As vital components in molds, punches significantly impact the mold’s proper functioning. During operation, Carbide punches play important roles such as enhancing needle strength and preventing needle deformation and bending. According to their materials, shapes, and applications, punches include SKD, SKH, ASP punches, guide punches, knockout punches, tooth punches, inspection punches, hexagonal punches, elliptical needles, forming punches, fan-shaped punches, irregular punches, high-speed steel punches, and high-quality hard alloy punches. Among them, high-quality carbide punches are also known as tungsten carbide punches.

During the machining process, there are high demands placed on punches because they experience severe friction with the mold cavity surface during plastic deformation. If punches are not wear-resistant, production work becomes challenging. Therefore, wear resistance is crucial for punches. Generally, the higher the hardness of a punch, the lower its wear rate, resulting in better wear resistance. Furthermore, the wear resistance of punches is closely related to the form, size, type, and quantity of carbides in the material.

Overall, carbide punches are indispensable in mold manufacturing due to their durability, precision, and ability to withstand demanding operational conditions.

Hard metal tungsten carbide punches manufacturer,Carbide Punch and Die Insert machining is our specialty. Welcome to contact us for an inquiry. We will respond as soon as possible.