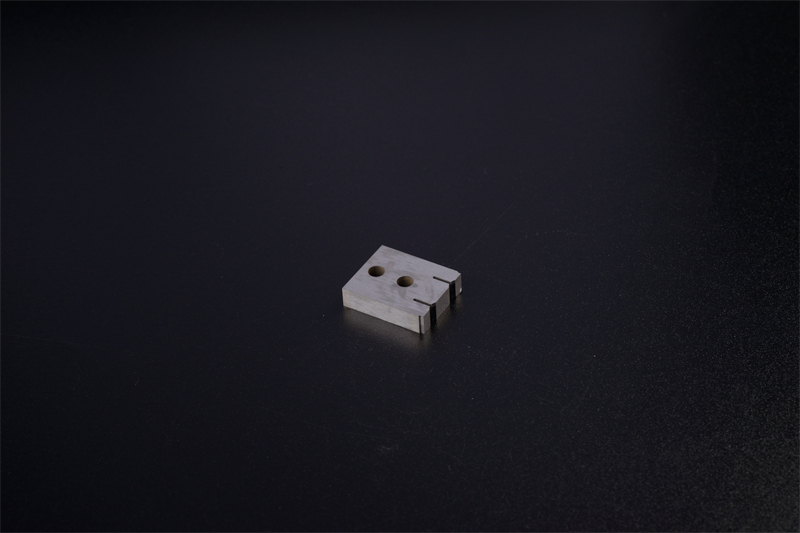

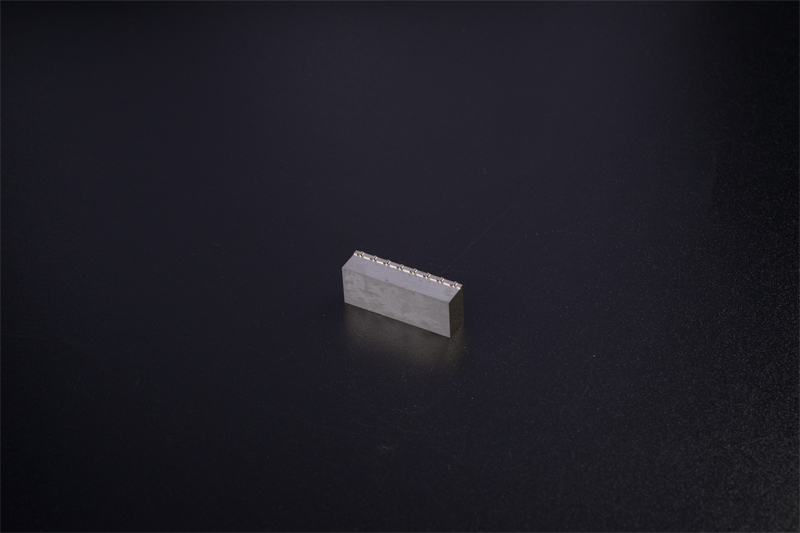

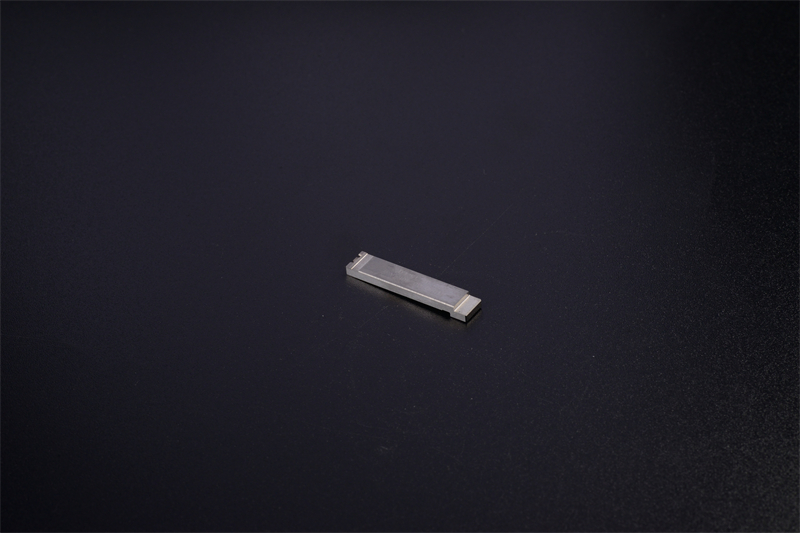

Wire cutting abrasive profile

Get Latest Price| Transportation: | Ocean |

Model No.: ys6

Brand: yushun

Place Of Origin: China

| Selling Units | : | Piece/Pieces |

The choice of wire cutting abrasive profile depends on the material being cut, the desired finish, and the cutting speed required.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.