Precision plastic molds are essential tools used to shape plastic materials into complex and highly accurate parts. These molds are designed to produce plastic components with minimal tolerances and high repeatability. They are widely used in various industries, including automotive, aerospace, medical devices, and consumer electronics, where exacting standards are crucial.

The process of creating

precision plastic mold Parts involves several stages, each requiring high levels of expertise and technological precision:

Design and Prototyping: The first step in mold creation is designing the mold using advanced CAD (Computer-Aided Design) software. Prototypes may be created using 3D printing or CNC (Computer Numerical Control) machining to validate the design before full-scale production begins.

Material Selection: High-quality steel or aluminum is typically chosen for precision molds due to its durability and ability to withstand the high pressures and temperatures involved in the molding process.

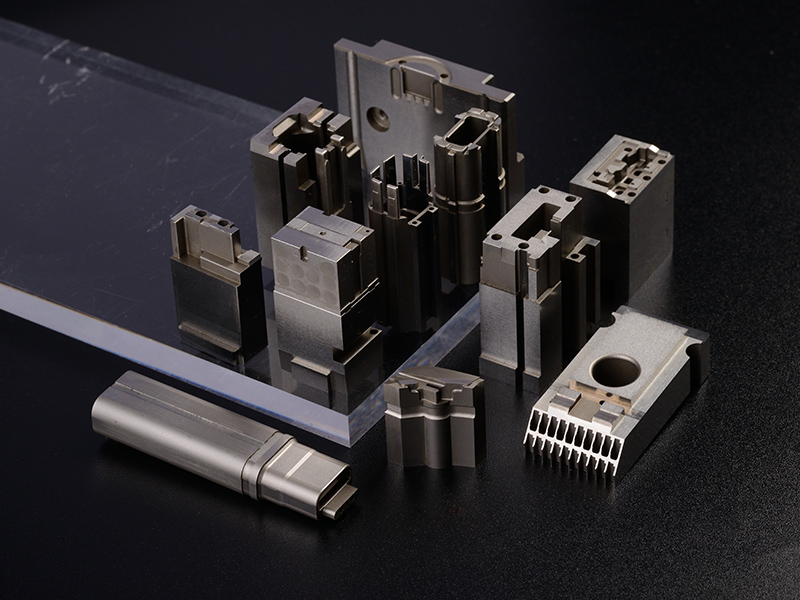

Machining: The core and cavity of the mold are machined to the precise specifications required. This process often involves CNC milling, EDM (Electrical Discharge Machining), and other high-precision techniques to achieve the desired shapes and tolerances.

Assembly: After machining, the mold components are assembled, and the cooling, ejector, and runner systems are integrated. This stage ensures that all components function together harmoniously.

Testing and Adjustment: The assembled mold is tested using trial runs to check for any issues. Adjustments are made as necessary to perfect the mold’s performance and to ensure that it meets all design specifications.

Precision Plastic Mold Parts Manufacturing Process and Quality Control

Maintaining high quality throughout the manufacturing process is critical to producing reliable and accurate plastic molds. The following are key elements of the manufacturing process and quality control measures:

Quality Assurance During Design and Machining: Rigorous quality checks are conducted during the design phase to ensure that the mold’s design adheres to all specifications. During machining, precision tools and techniques are used to maintain tight tolerances.

Inspection and Testing: Once the mold is assembled, it undergoes a series of inspections and tests. This includes checking the mold’s dimensions, surface finish, and functionality through trial molding. Advanced measurement tools, such as CMM (Coordinate Measuring Machines), are used for detailed inspections.

Material Testing: The materials used in the mold are tested for hardness, durability, and other mechanical properties to ensure they can withstand the stresses of the molding process.

Process Control: Throughout the production run, the molding process is closely monitored to ensure consistency. This includes controlling factors such as temperature, pressure, and cooling rates to produce high-quality plastic parts.

Continuous Improvement: Feedback from trial runs and production batches is used to make continuous improvements to the mold design and manufacturing process. This iterative approach helps in identifying and resolving potential issues early, leading to better performance and longer mold life.

Precision plastic mold Parts manufacturing is a complex and meticulous process that requires a blend of advanced technology and skilled craftsmanship.