Core and cavity customization in injection molding

Get Latest Price| Payment Type: | Paypal,Others |

| Transportation: | Ocean |

| Payment Type: | Paypal,Others |

| Transportation: | Ocean |

Model No.: ys19

Brand: yushun

Place Of Origin: China

| Selling Units | : | Piece/Pieces |

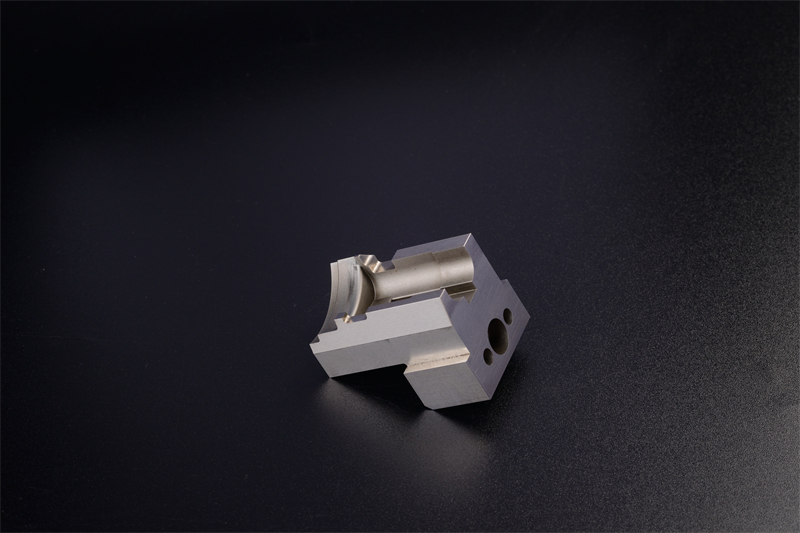

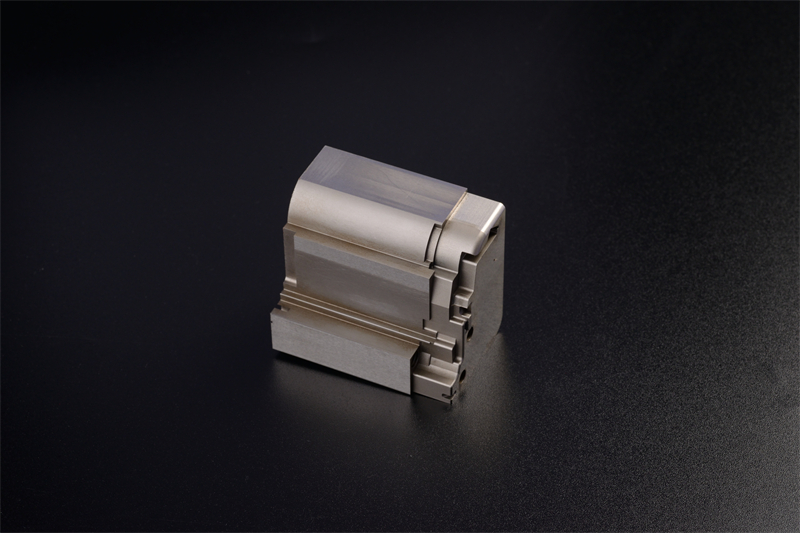

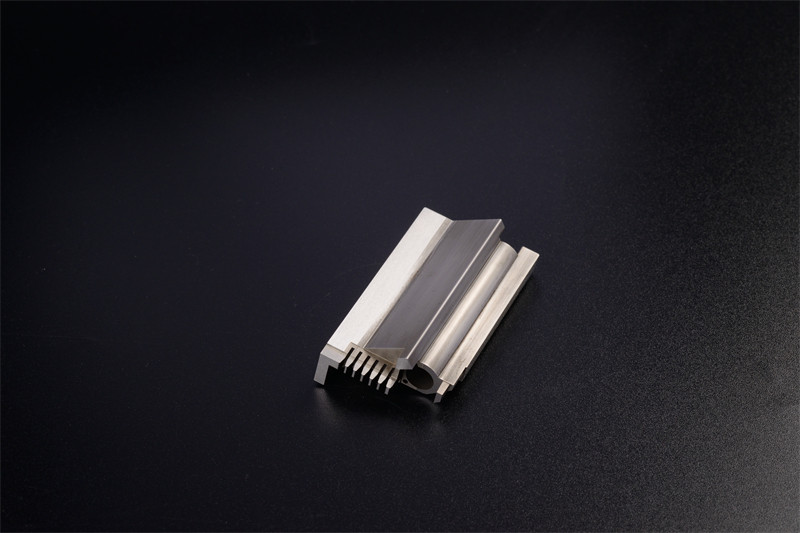

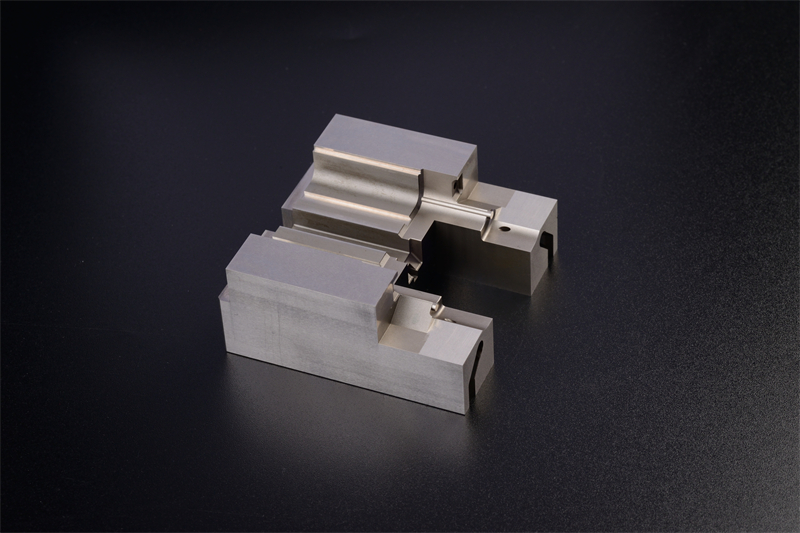

Precision Electronic Consumer Moulds

Core and cavity customization is an important aspect of injection molding that allows for the creation of complex parts with precise features. The core and cavity are the two halves of the mold that create the shape of the plastic part.

Customization of the core and cavity involves tailoring the shape, size, and features of these components to match the requirements of the desired part. This may involve creating complex shapes, varying wall thicknesses, and incorporating features such as undercuts or threads.

One common approach to customizing core and cavity design is through the use of computer-aided design (CAD) software. This allows designers to create detailed 3D models of the core and cavity based on the part specifications. These models can then be used to guide the fabrication process, ensuring that the mold components match the desired part geometry.

Precision Electronic Consumer Moulds display

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.