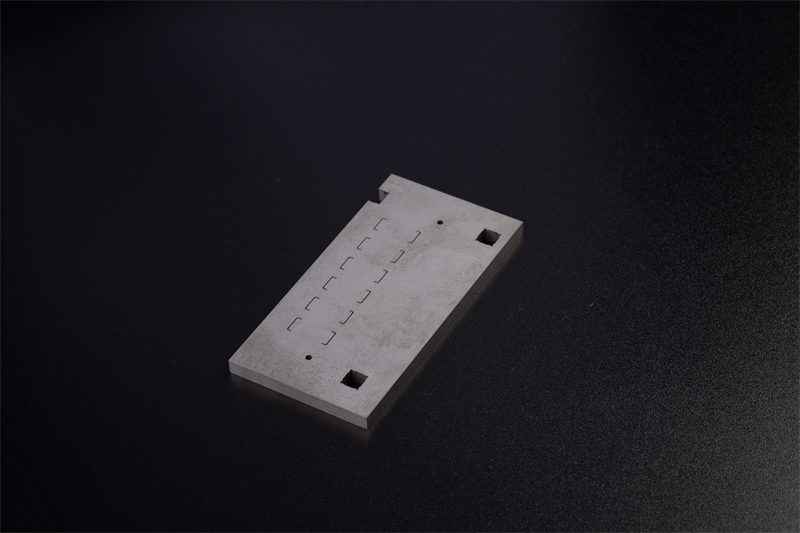

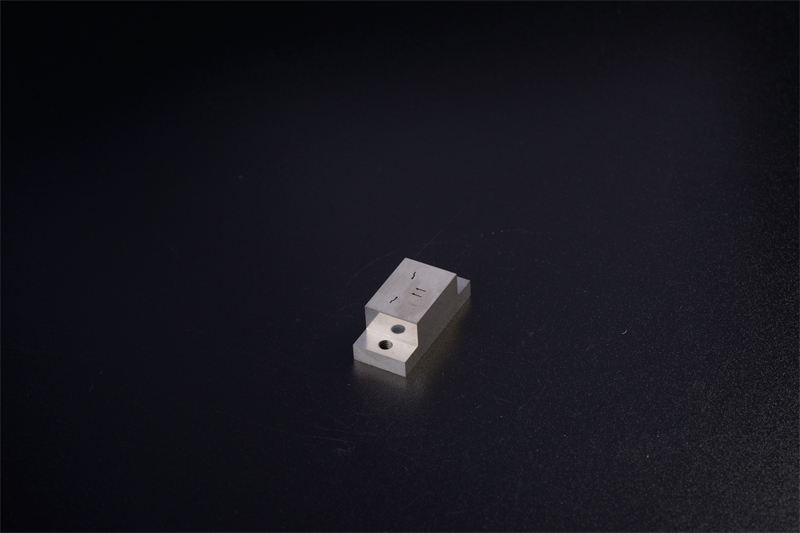

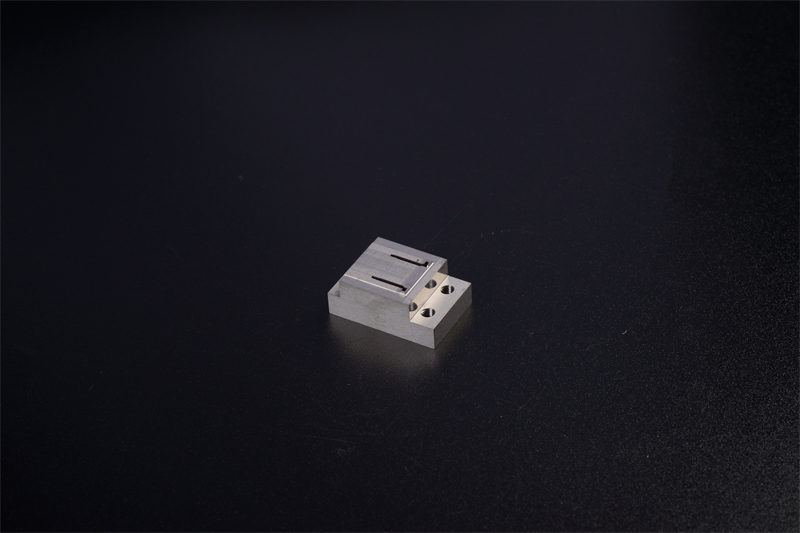

Customized wire cutting oil cutting molding mold parts

Get Latest Price| Payment Type: | Paypal,Others |

| Transportation: | Ocean |

| Payment Type: | Paypal,Others |

| Transportation: | Ocean |

Brand: yushun

Place Of Origin: China

| Selling Units | : | Piece/Pieces |

Because the oil cutting slow wire processing adopts the method of continuous wire electrode feed, that is, the wire electrode is processed in the process of motion, even if the wire electrode is lost, it can be constantly supplemented, so as to improve the machining accuracy of parts. The workpiece surface roughness of oil cutting slow wire processing can usually reach Ra=0.8μm or more. The roundness error, straightness error and size error of oil cutting slow wire processing are much better than that of fast Wire cutting. Therefore, oil cutting slow wire processing has been widely used in high-precision parts, except for early small and medium-sized companies, such as Chinese airlines, automobiles, It is also common in large logistics processing plants such as medical treatment.

What are the characteristics of oil cutting precision? Let's take a look at it.

1. Multiple cutting technology. Multiple cutting technology is the fundamental means to improve the machining precision and surface quality of slow wire. It is the scientific combination of design and manufacturing technology, CNC machine tool technology, intelligent technology, pulse power technology, precision transmission and control technology. Generally, it is through one cutting forming, two cutting to improve the accuracy of work, and more than three cutting to improve the quality of students' surface engineering. In order to achieve high quality surface, the number of multiple cuts needs to be as high as 7 ~ 9 times, only 3 ~ 4 times.

2. Corner machining technology is constantly optimized and perfected. In order to improve the precision of corner cutting, more dynamic corner processing strategies are adopted. For example, changing the wire path, changing the machining speed (thin sheet), automatically adjusting the water pressure, machining energy, etc., using the integrated corner control strategy, the corner shape error in rough machining can be reduced by 70%, and the cutting accuracy can reach more than 5.

3. Use techniques to improve flatness.

High precision finishing circuit is a technique to improve flatness, which is of great significance to machining thick parts.

4. Machine tool structure is more precise. In order to ensure high precision processing, a number of technical management measures are adopted to improve the accuracy of the main engine: control the ambient temperature, the internal temperature of the machine is the same as the water temperature, and the thermal deformation of the machine is reduced. Linear motor, high response, precision positioning can achieve 0.1μm equivalent control, feed without vibration, no noise, improve discharge frequency, maintain stable discharge, two cutting Ry5μm, ceramic and polymer granite thermal inertia is 25 times larger than cast iron, the impact of temperature changes on the cutting accuracy is reduced. Adopt fixed table and column moving structure, improve the bearing capacity of the table, not affected by the workpiece water immersion process and weight changes. Using impregnation process, reduce the thermal deformation of the workpiece. Motor servo, closed loop wire tension control. High precision tool: using different voltage modulation tool power supply. Tool setting accuracy can reach. 0.005mm, no damage to the workpiece, whether wet or dry.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.