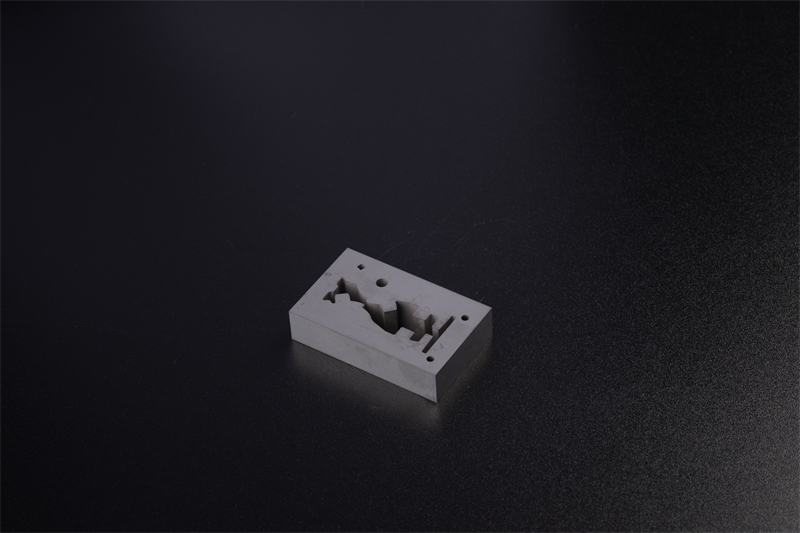

In our daily Precision Hardware Mould Processing, we usually use the discharge processing process, the following small series explains the discharge processing process in detail

First, classification of EDM

1, ordinary EDM: This type of processing is mainly the use of ordinary flame electrode in the electrolyte spark effect, so as to achieve the purpose of positioning and cutting metal materials, this type of processing is mainly used for the processing of small devices.

2, precision EDM: This type of machining is a processing technology developed on the basis of ordinary EDM, which has high positioning accuracy, high cutting precision, 2 or more stations can be processed in parallel, the surface quality of the machining is excellent, more conducive to mass processing and rapid production, such processing is mainly used for the processing of large devices.

3, ultra-precision EDM: This type of machining is a processing technology developed on the basis of precision EDM, which has higher positioning accuracy, higher cutting accuracy, 3 or more stations can be processed in parallel, better surface quality and other characteristics, such processing is mainly used for the processing of very small devices.

Second, the characteristics of EDM for

Precision Hardware Mould Processing 1, high machining accuracy: the hole size accuracy of EDM can reach 0.005mm, the hole Angle accuracy can reach 0.1mm, the hole wall finish is high, the hole surface roughness is generally Ra0.4mm, which is unmatched by traditional processing technology.

2, high processing efficiency: the speed of

EDM Machining can reach 1500-2000 m per hour, far more than the manual control of processing, so effectively shorten the time spent in processing, can more efficiently meet the mass production, special requirements of processing needs.

3, good processing flexibility: EDM can flexibly adjust the processing technology based on the design, according to the needs of different workpiece sizes, processing density and directional rotation, using the appropriate parameters for processing, thus greatly improving the processing accuracy of the machined surface and faster processing efficiency.

4, accuracy can be controlled by the user: traditional processing technology, positioning accuracy has nothing to do with processing performance, and the positioning accuracy of EDM can be controlled to a certain extent, with strong convenience and flexibility, so that the processed finished products can exceed the limit requirements of traditional processing technology.

Third, the processing process of EDM

Edm processing process:

1. Preparatory work

Design according to the production drawings and processing requirements.

2, clean liquid material

Clean the materials used for processing to prevent inclusions from affecting the processing accuracy.

3, processing parameter setting

According to different materials and processing requirements to determine the processing parameters, including electrode type, depth, circuit number, etc.

4, position positioning

Positioning to the fixed coordinate system of the machining table to ensure the machining accuracy.

5. Processing

According to the set machining parameters, the machining program is opened, and the machining and cutting are controlled by the equipment.

6. Security check

Check the finished hole position and Angle to avoid inaccurate machining results.

7. Cleaning and other work

Clean up the processed materials, check whether the equipment is normal, and other matters.

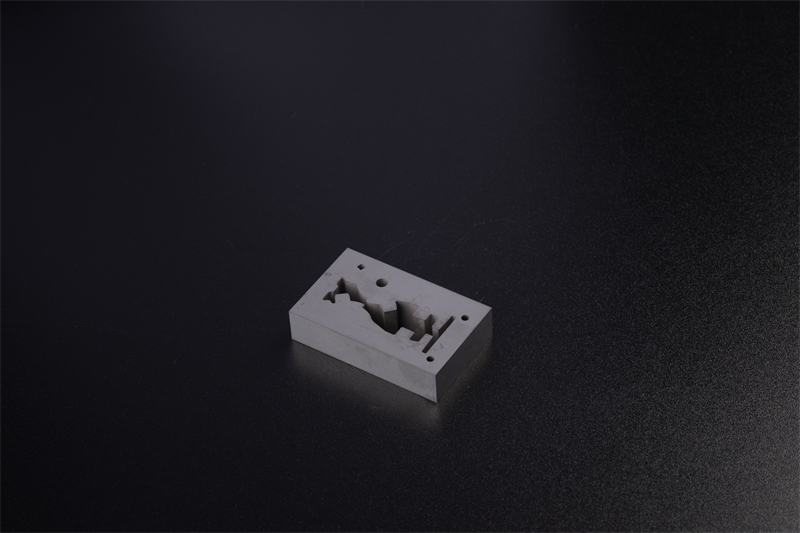

Fourth, finished product quality requirements

Finished product quality requirements of EDM:

1, positioning accuracy

The positioning accuracy of EDM can generally reach 0.02mm, and the positioning accuracy can have different requirements according to different materials and processing requirements.

2. Accuracy

According to the processing requirements, the processing parameters are determined to ensure the accuracy of the processing, so as to achieve the hole size and hole Angle.

3. Finish

The finish requirement of the machined surface can generally reach Ra0.8, and the finish requirement can have different requirements according to different materials and processing requirements.

4. Roughness

The roughness requirements of the machined surface can generally reach Ra0.4, and the roughness requirements can have different requirements according to different materials and processing requirements.

Five, EDM operation points

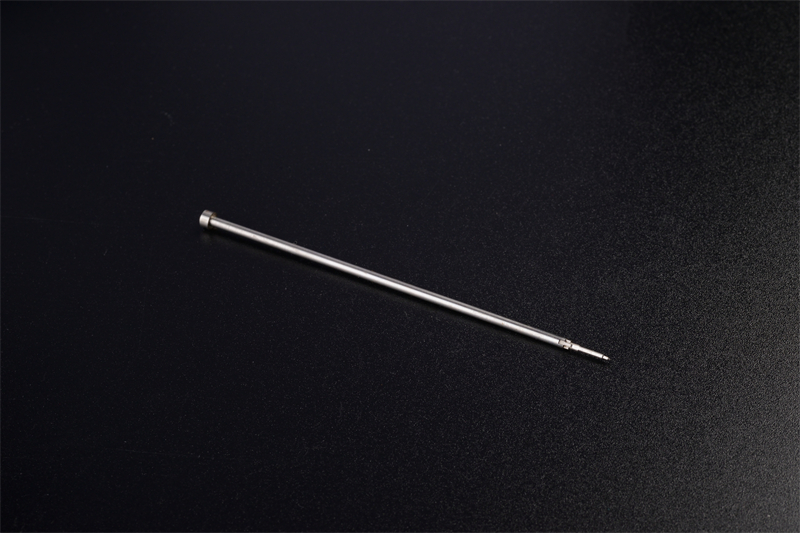

1. Check the electrode

In the processing process, the state of the electrode should be frequently checked, such as the wear resistance of the electrode, the degree of wear, etc., to ensure the processing accuracy.

2. Adjust the electrode

During processing, the electrode should be adjusted regularly to ensure processing accuracy.

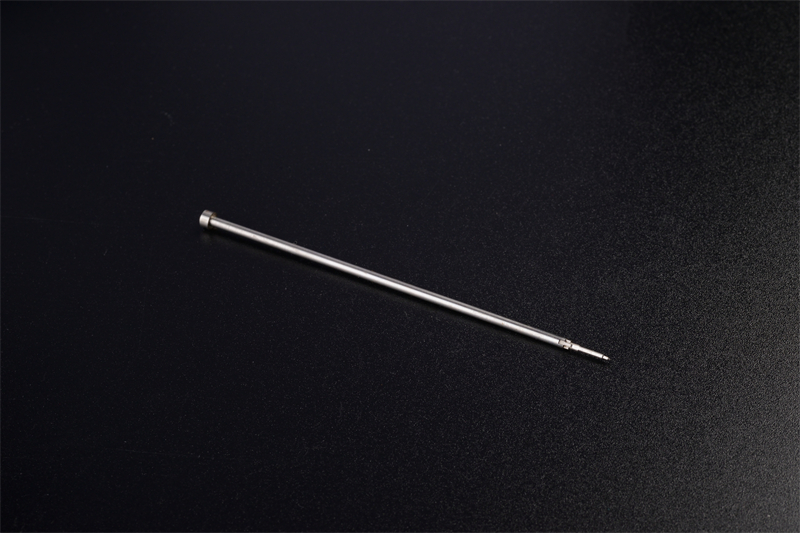

3, control the processing time

The EDM processing time should not be too long to prevent electrode wear and affect the processing accuracy.

4, control the depth of processing

The processing depth should be adjusted according to the processing requirements to ensure the processing accuracy.

5. Maintain the equipment

The equipment should be maintained regularly to ensure the normal use of the equipment.

6. Precautions for EDM

1, the choice of processing technology

According to the processing requirements, select the appropriate processing technology to ensure the processing accuracy.

2, safe operation

During the processing, pay attention to safety and avoid accidents.

3, electrode replacement

Replace the electrode regularly to ensure the machining accuracy.

4. Clean the equipment

The equipment should be cleaned regularly to ensure normal use of the equipment.

5. Adjust parameters

According to processing requirements, reasonable adjustment of processing parameters to ensure processing accuracy.

6. Prepare tools

The necessary tools should be prepared for operation during processing.

7. Check the finished product

The finished product should be checked regularly to ensure machining accuracy.