PG

Optical Curve Grinding parts referred to as PG processing, mainly used for processing stamping die and other key parts of precision equipment, suitable for high hardness materials forming and grinding.

With more and more enterprises and factories engaged in PG optical curve grinding parts, the market competition is becoming larger and larger, gradually slipping from quality competition to price competition, compared with 10 years ago, the overall market environment is in a downward trend, the reason for the continued growth of PG machining is the increase in market demand and the improvement of customer requirements for the accuracy of processing workpiece, which conveys a signal from the side. -- The future development direction is advanced and sophisticated.

Of course, in the development trend of PG in China, we can see the shadow of PG in Japan and Taiwan Province, which also points out some problems from some aspects.

On the processing accuracy of machine tools, the entire industry has upgraded from fast wire to

Wire cutting, due to market demand, the fast line is slowly declining, and the middle line is in line with the trend.

However, with the improvement of the processing accuracy requirements of some parts, PG optical curve grinding parts came into being, and PG optical curve grinding parts are gradually accepted and favored by enterprises requiring high precision.

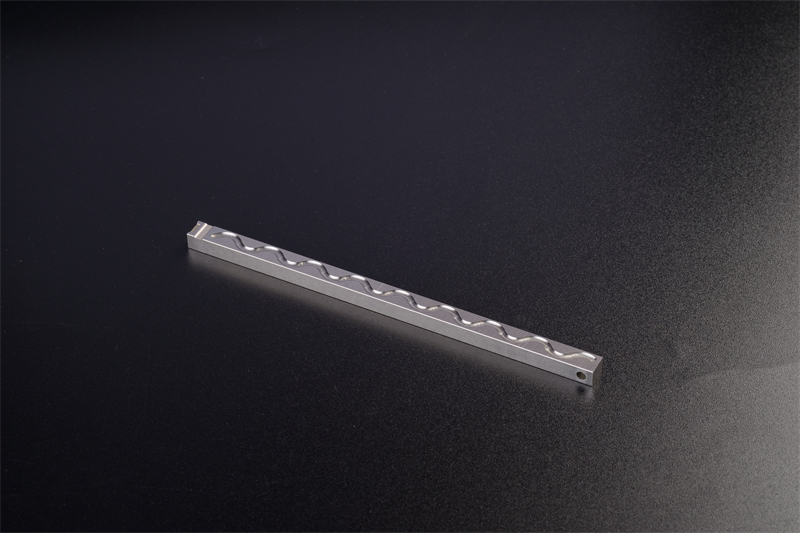

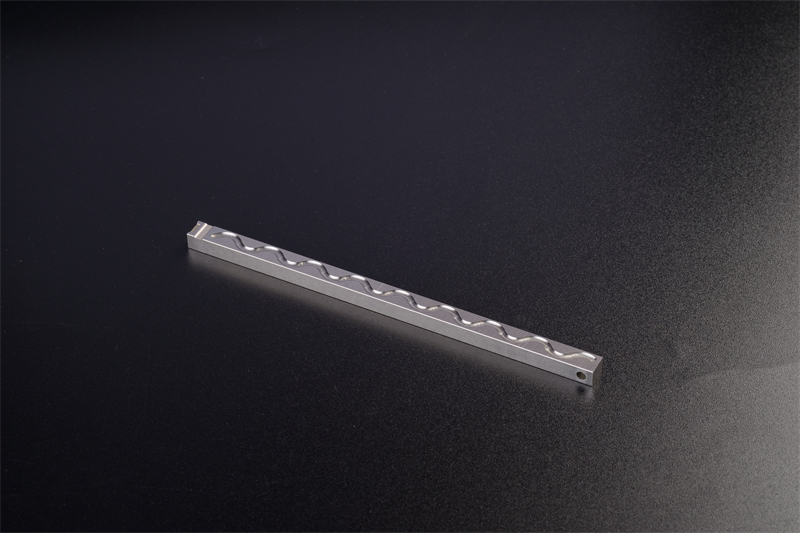

PG optical curve grinding parts processing

1. In terms of processing accuracy, PG optical curve grinding parts can reach 1um;

2. The precision control of R Angle can also reach 0.001mm;

3. It has a better finish, with PG optical curve grinding products, the side looks like a mirror, the front is also very beautiful, the line is very small;

4.PG optical curve grinding parts have high durability and long life.

Do you know the difference between JG and PG treatment? Today, Xiaobian to tell you the difference between JG and PG processing.

Although they only have a letter difference, but in fact, they do not have anything in common, people like to compare them together, because these two processing methods are commonly used in precision mold processing high-precision processing technology, is our mold people often mentioned processing methods, such as you ask me what kind of processing Jintai precision can do, I will tell you that we can do JG machining, PG machining, wire cutting water cutting oil cutting, if people who are not familiar with machining hear JG machining and PG machining.

The first is the working principle, JG processing adopts the planetary hole grinding method, grinding the workpiece with the wheel as the tool, PG processing is a high-precision processing projected on the screen by the optical projector according to the size of the workpiece with a magnification of 20-50 times.

Secondly, the processing object is different, JG mainly processing internal and external round holes, cone holes, square holes, shaped holes, etc., processing accuracy within 0.002mm, PG mainly processing stamping die knife edge and punch, high-precision punch, lower die insert, stripper and other workpiece, processing accuracy is 0.001mm, even the grinding wheel they use is not the same, JG coordinate grinding machine mainly uses grinding rod, mainly used to grind hole wall and shape, can grind to a high finish and accuracy, PG optical grinding mainly uses knife sand wheel, similar to a knife, can process small R Angle and groove.