Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

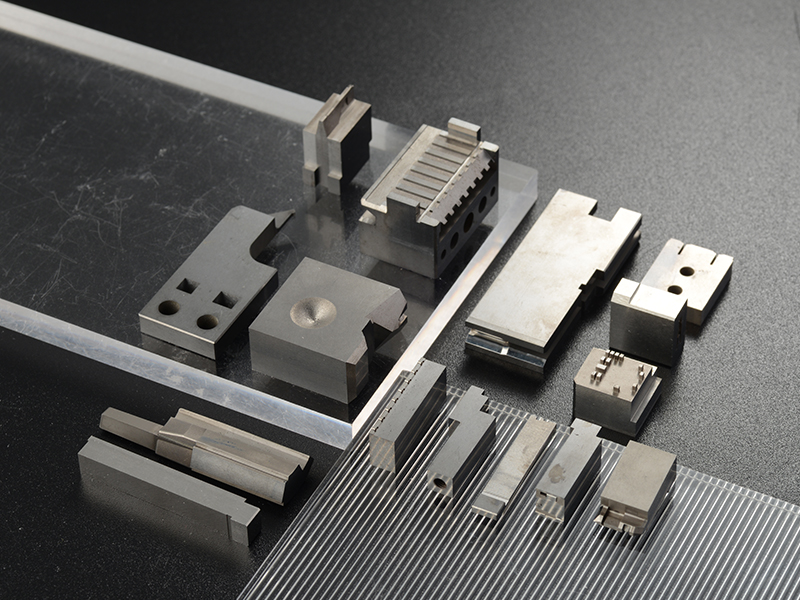

Mold Classification: Before production, the structural types of molds should be classified to reasonably select processing equipment and process routes, thereby improving machining efficiency and accuracy.

CNC Turning Technology: Suitable for machining of rotational mold parts, it can control dimensions to meet process requirements and ensure the quality of mold machining.

Electrical Discharge Machining (EDM) Technology: Suitable for deep processing of molds, adjusting process parameters to ensure the surface quality and accuracy of the processed molds.

CNC Milling Technology: Suitable for complex structure mold machining, ensuring the mold accuracy meets technical requirements.

Technical Personnel Training: Strengthen the professional technical training of CNC equipment operators, familiar with the preparation and verification of cnc machining programs, and master the control of parameter accuracy.

Optimize Machining Processes: Continuously optimize existing machining processes and introduce new technologies to improve mold machining accuracy and effectively control the machining process accuracy.

Mold Rapid Prototyping Technology: Using 3D printing technology for rapid mold prototyping to ensure the accuracy of parts.

Precision Cutting Technology: Using electronic control for material cutting, improving cutting accuracy and reducing scrap removal.

Ultra-precision Grinding Technology: Grinding parts after mold machining and forming, repairing deformation after heat treatment, and improving surface roughness.

Simulation Stamping Forming Technology (CAE): Adjust mold accuracy through CAE technology to reduce production costs and shorten production cycles, and improve dimensional accuracy.

Structural Design Optimization: Reasonable mold structural design can ensure product accuracy and stability, and improve production efficiency.

Material Selection: Choose materials with high hardness, wear resistance, heat resistance, and corrosion resistance to ensure the service life of the stamping die.

Machining Processes: Pay attention to the selection of cutting tools, the choice and adjustment of machining equipment, and reasonably arrange the machining order to reduce machining errors.

Heat Treatment: Improve the hardness and toughness of the mold through heat treatment to increase service life and reduce wear.

August 27, 2024

August 27, 2024

Mirror grinding and surface grinding are two different processes used for shaping and finishing flat surfaces, but they differ in their goals and methods. Mirror grinding is a specialized process...

Email to this supplier

August 27, 2024

August 27, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.