Optical projection grinding (PG) processing refers to a method used in precision manufacturing to achieve high-quality and accurate surfaces on optical components. It involves using a computer-controlled grinding machine with a specially designed tool called a grinding wheel to shape and finish optical surfaces.

The process begins with the design and fabrication of the grinding wheel. The wheel is typically made of diamond or other abrasive materials and is shaped to match the desired surface profile of the optical component. The optical component, such as a lens or mirror, is then mounted onto a precision rotary table.

The grinding machine uses a projection system to project a magnified image of the desired surface profile onto the surface of the optical component. This image is aligned and matched to the component's surface, allowing the operator to precisely control the shape and depth of the grinding process.

During grinding, the operator adjusts various parameters such as the rotational speed of the component, the feed rate of the grinding wheel, and the position of the grinding tool, based on the projected image and the desired surface specifications. The grinding wheel removes material from the optical component, gradually bringing it into conformity with the desired profile.

The PG processing method offers several advantages over other traditional grinding methods. It allows for greater control and accuracy in shaping optical surfaces, resulting in improved optical performance and reduced manufacturing errors. The projection system enables operators to visualize the grinding process, making it easier to achieve specific surface profiles and eliminate surface defects.

Optical projection grinding is commonly used in the production of various optical components, including lenses, mirrors, prisms, and filters. It is often employed in the fabrication of high-precision optics for applications such as telescopes, cameras, microscopes, lasers, and other optical instruments.

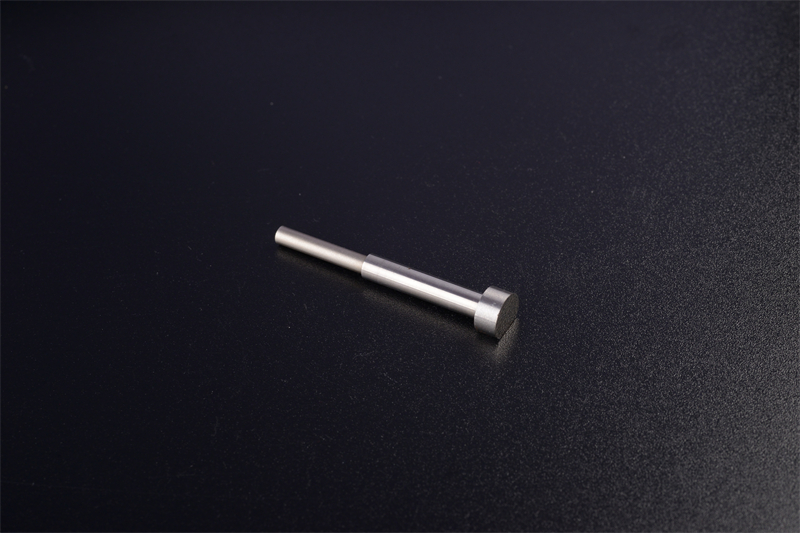

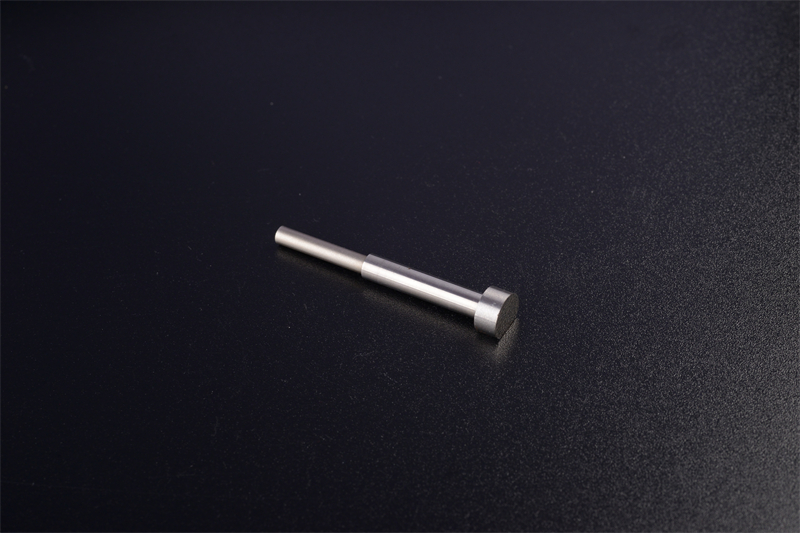

In the production of mold parts

optical projection grinding is a highly precise and efficient method for manufacturing optical components with excellent surface quality, ensuring optimal performance in various optical systems.