Electrical Discharge Machining (EDM) stands at the forefront of modern manufacturing techniques, revolutionizing the production of intricate parts and molds. This article aims to elucidate the fundamentals of EDM Machining, its diverse applications in mold fabrication, and the nuanced processes involved in shaping various types of molds.

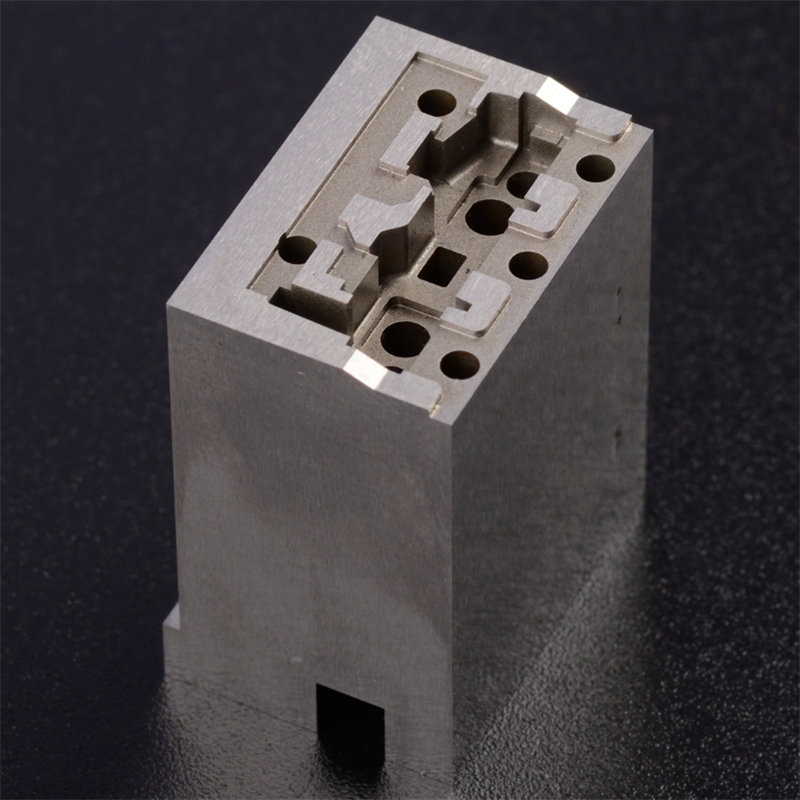

EDM machining, also known as spark erosion machining, is a precision manufacturing process that utilizes electrical discharges to selectively remove material from a workpiece. Unlike conventional machining methods that rely on physical contact, EDM operates by generating controlled sparks between an electrode and the workpiece, eroding material with exceptional precision. This non-contact approach enables the fabrication of complex shapes and contours with unparalleled accuracy, making it an indispensable technique in modern manufacturing.

EDM Machining Forming Processing Method

The EDM machining process unfolds through the following steps:

1.Workpiece Preparation: The mold material, typically a conductive metal such as steel or aluminum, is meticulously prepared and mounted on the EDM machine’s worktable.

2.Electrode Selection: An electrode, often made of graphite or copper tungsten, is chosen based on the desired shape and material compatibility with the workpiece.

3.Dielectric Fluid Setup: The workpiece and electrode are submerged in a dielectric fluid, such as deionized water or oil, to facilitate the electrical discharge and dissipate heat generated during machining.

4.Toolpath Programming: Using computer-aided design (CAD) software, the desired geometry of the mold is meticulously programmed, delineating the precise toolpath for the electrode.

5.Machining Operation: The EDM machine precisely controls the movement of the electrode, generating electrical discharges that erode material from the workpiece according to the programmed toolpath.

6.Surface Finish Evaluation: Upon completion of machining, the surface finish of the mold undergoes thorough inspection to ensure compliance with the required specifications.

7.Finishing Touches: Any remaining rough edges or burrs are meticulously addressed through deburring or polishing processes to achieve the desired surface quality.

Performing EDM Machining on Various Types of Molds

EDM machining is adept at fabricating a wide range of molds, including:

Injection Molds: Used in plastic injection molding processes, EDM machining precisely carves intricate cavities and cores to produce high-quality plastic components.

Die Casting Molds: EDM enables the fabrication of precise die casting molds for manufacturing metal components with complex geometries.

Stamping Dies: EDM machining is employed to create stamping dies used in sheet metal forming processes, ensuring the production of precise and consistent parts.

Extrusion Dies: By utilizing EDM, manufacturers can craft intricate extrusion dies for producing profiles and shapes in materials like aluminum, steel, and plastics.

Blow Molds: EDM machining facilitates the fabrication of blow molds used in the production of hollow plastic containers, such as bottles and containers.

In each case, EDM machining offers unparalleled precision and flexibility, enabling manufacturers to produce molds with intricate details and tight tolerances to meet the demands of diverse industries.

EDM machining stands as a cornerstone in the realm of mold fabrication, offering unmatched precision and versatility in producing intricate molds for various manufacturing processes. By understanding the fundamentals of EDM machining and its application in mold fabrication, manufacturers can harness this advanced technology to streamline production processes, enhance product quality, and drive innovation in the ever-evolving landscape of modern manufacturing.