Wire Electrical Discharge Machining (EDM) stands as a cornerstone in the realm of modern manufacturing, offering a unique set of advantages for precision machining intricate parts. This article delves into the core characteristics of wire EDM, its sequential processing steps, and the extensive array of materials it can proficiently manipulate.

Wire EDM is distinguished by several key characteristics:

1.Non-Contact Precision: Unlike traditional machining methods that rely on physical contact between the tool and the workpiece, wire EDM employs electrical discharges to precisely erode material, making it particularly suitable for delicate components.

2.Exceptional Accuracy: Wire EDM can achieve remarkably tight tolerances, often within microns, ensuring the production of parts with meticulous geometries and dimensions.

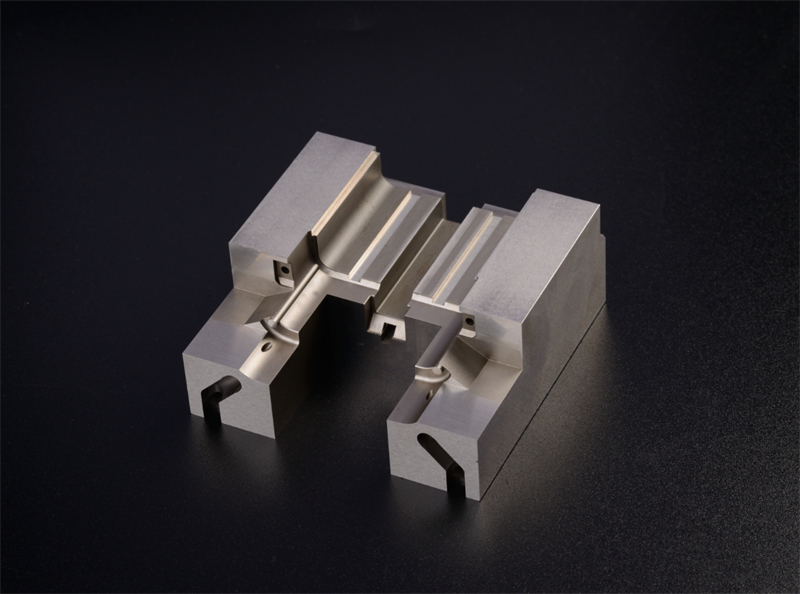

3.Capability for Complex Shapes: Its prowess in cutting intricate shapes and contours, including sharp internal corners and deep recesses, positions wire EDM as an indispensable tool for crafting complex components and molds.

4.Minimal Material Disturbance: The non-mechanical nature of wire EDM minimizes mechanical stresses on the workpiece, rendering it suitable for materials prone to deformation or cracking during conventional machining.

5.Versatility Across Materials: Wire EDM can effectively machine a diverse range of conductive materials, spanning metals, alloys, and even conductive ceramics, thereby broadening its applicability across various industrial sectors.

The process of wire EDM machining unfolds through the following sequential steps:

1.Workpiece Preparation: The workpiece is meticulously mounted on the machine’s worktable, ensuring steadfast stability during the machining operation.

2.Toolpath Programming: Employing computer-aided design (CAD) and computer-aided manufacturing (CAM) software, the desired toolpath for the wire electrode is meticulously programmed, delineating the precise geometry and dimensions of the intended part.

3.Wire Installation: A spool of electrically conductive wire, typically composed of brass or coated with brass, is methodically threaded through the wire EDM machine’s guides and tensioning system.

4.Dielectric Fluid Setup: The workpiece and wire electrode are submerged in a dielectric fluid, commonly deionized water, which serves as a conduit for electrical discharges and aids in flushing away machining debris.

5.Machining Operation: The wire electrode is intricately controlled by the machine’s CNC system, generating precisely timed electrical discharges that gradually erode material from the workpiece along the predefined toolpath.

6.Surface Finish Evaluation: Upon the completion of machining, the surface finish of the part undergoes meticulous inspection to ascertain compliance with the requisite specifications. Supplementary finishing processes may be employed to further refine surface quality, if deemed necessary.

7.Workpiece Retrieval: Subsequent to the machining operation, the finished part is extracted from the machine, with any residual burrs or rough edges meticulously addressed through deburring or analogous finishing techniques.

Material Ranges of Wire EDM Machining

Wire EDM exhibits proficiency in machining a diverse spectrum of conductive materials, encompassing:

· Metals: Including but not limited to steel, stainless steel, aluminum, copper, titanium, and their respective alloys.

· Tool Steels: Encompassing high-speed steels and hardened tool steels prevalent in mold and die making applications.

· Exotic Alloys: Such as Inconel, Hastelloy, and Monel, frequently encountered in aerospace and chemical processing realms.

· Conductive Ceramics: Certain ceramics boasting high electrical conductivity, such as silicon carbide and tungsten carbide, can also be effectively machined utilizing wire EDM.

The versatility of wire EDM in navigating through various materials positions it as the preferred choice across an extensive array of industries, spanning aerospace, automotive, medical device manufacturing, and electronics.

Wire EDM machining epitomizes precision, versatility, and efficiency in crafting intricate components with meticulous precision. By comprehending its distinctive characteristics, sequential processing steps, and material compatibility, manufacturers can harness this advanced machining technology to address the exigencies of contemporary manufacturing across diverse industrial landscapes. As technological advancements continue to unfold, wire EDM remains poised as an indispensable asset in the arsenal of precision machining techniques, propelling innovation and facilitating the realization of increasingly intricate and precise components.