Perfect Wire EDM Cutting technology

April 12, 2024

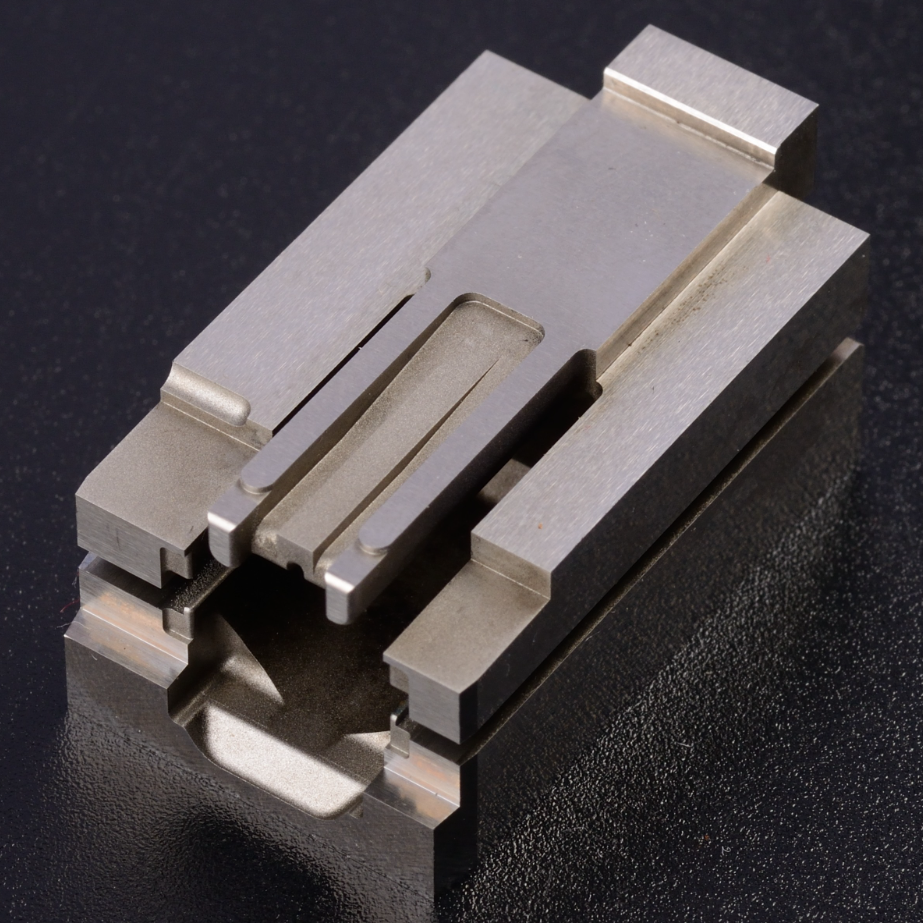

How are the perfectly fitting parts cut? Why are there almost no cutting marks?

In traditional cutting, even when using a very fine wire to cut foam board, there are usually noticeable cutting traces and relatively large gaps. However, for metal parts like these, no machining traces are visible. How is this achieved? In reality, they are cut from two separate metal blocks, and achieving their perfect fit requires a high-precision cutting technique—wire edm cutting.

This cutting technique can achieve details on metal finer than a strand of hair, with a machining accuracy of up to 0.001 millimeters, something traditional methods cannot achieve. wire edm cutting uses extremely fine wires for cutting, but without making direct contact with the workpiece. The process goes as follows: when the electrode is close enough to the metal workpiece to be cut but without touching it, applying high-frequency pulsed voltage to the wire generates electric sparks. The instantaneous high temperature produced by these sparks can reach 8000 to 12000 degrees, melting the workpiece instantly.

To prevent the workpiece from accumulating excessive heat and to clear away the metal debris generated during cutting, the cutting is usually performed in a special non-conductive cooling liquid, known as deionized water. It’s worth mentioning that the entire cutting process is controlled by precise numerical control (CNC) technology. This technology can accurately control the position and movement speed of the electrode, ensuring precise and error-free cutting paths. As a result, complex shapes and unparalleled details can be cut out.

Wire EDM Machining was once considered a non-traditional machining method, but it has now been used for many years and widely applied in various industries. It’s a unique machining process that can achieve ultra-high precision in processing most conductive materials, producing a variety of application parts.