Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

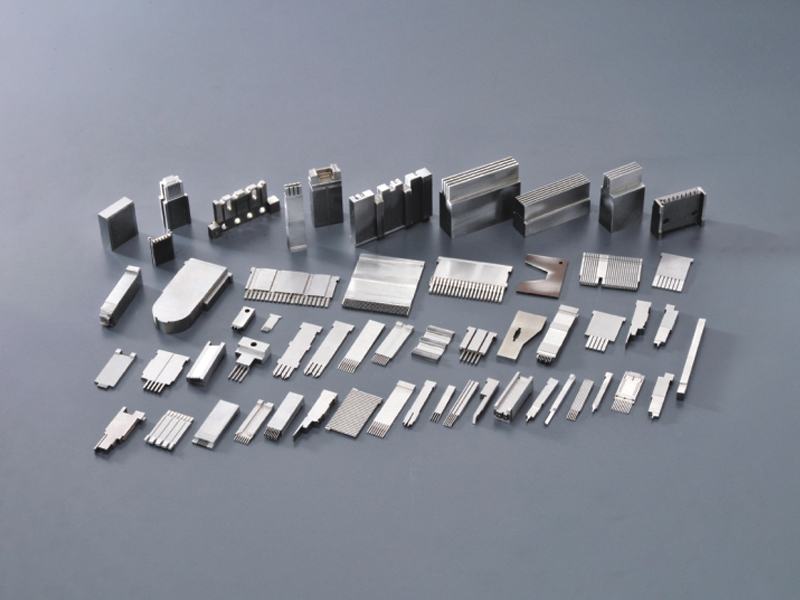

Electrical edm machining is the most widely used processing method in the electrical machining industry, accounting for about 90% of the industry. According to the relative movement between the tool electrode and the workpiece, it can be roughly divided into EDM forming, Wire cutting, EDM grinding, EDM synchronous conjugate rotary machining, EDM high-speed small hole machining, EDM surface strengthening and Six categories including lettering and processing. Among them, wire cutting processing accounts for 60% of EDM Machining, and EDM forming accounts for 30%. With the vigorous development of electrical machining technology, wire cutting processing has become a symbol of advanced technology production.

With the expansion of industrial production scale and the development of manufacturing technology, wire cutting technology, as a kind of special processing technology, has been widely used in mechanical processing production due to its high processing precision, high production efficiency, low power consumption, low manufacturing cost and other characteristics. Has been widely used.Especially in the mold processing industry, EDM technology is widely used in cold die and extrusion die processing, changing the past processing mode with separate die and curve grinding, shortening the manufacturing cycle, reducing manufacturing costs, and high precision.

August 27, 2024

August 27, 2024

Mirror grinding and surface grinding are two different processes used for shaping and finishing flat surfaces, but they differ in their goals and methods. Mirror grinding is a specialized process...

Email to this supplier

August 27, 2024

August 27, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.