Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

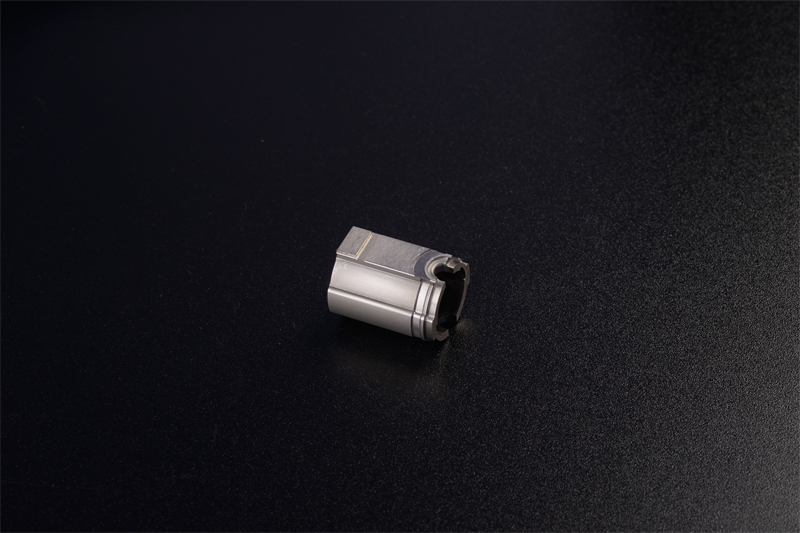

Mirror polishing of mold parts refers to the mold after the mirror polishing can be polished out of the mold like a mirror, to the mirror polishing level is already a very good quality, mirror polishing processing can not only create a high level of appearance for the mold, but also reduce the notch effect, extend the life of the mold

Common mold parts mirror polishing has the following three kinds:

1. One is called mechanical polishing. Generally,

this kind of mold polishing is a method of polishing the protruded part of the mold surface after cutting by machinery and equipment, plastic deformation of the material surface and polishing. This method generally requires the use of wool wheels, sandpaper and oilstone strips, etc., which are usually manually operated as the main method. More special molds can be polished using the auxiliary tools of the turntable. Generally, the mold with high surface quality requirements can use the method of ultra-fine grinding and polishing. This method generally refers to the need to use a specially made grinding disk or abrasive tool and with abrasive polishing liquid, polishing the mold tightly pressed on the surface of the mold to be processed. Then usually this technology can be used to polish the mold surface to a roughness of Ra0.008μm, mechanical polishing is the most common three kinds of mold polishing technology level requirements, but also the highest precision after polishing.

2. Then the second is chemical polishing, chemical polishing,

as the name suggests, is the use of chemical potion polishing, generally need to put the mold workpiece in the chemical medium, so that the workpiece surface has some protruding part of the priority to dissolve, in this way to get a smooth surface, the method of this method is no more complex equipment, Can polish a more complex shape of the workpiece. And it can polish many workpieces at the same time, and the efficiency is also high. However, the main problem of chemical polishing is the preparation of polishing liquid, and the accuracy requirement can only reach the surface roughness of 10μm, and the precision is not very high.

3. The third is electrolytic polishing,

the polishing principle of this polishing method is relatively the same as the principle of chemical polishing, that is, the small protruding part of the mold surface is polished by selectively dissolving materials, yes, the mold surface is relatively smooth, the mold polishing compared with chemical polishing, is able to eliminate the impact of the cathode reaction, the polishing effect is better.

August 27, 2024

August 27, 2024

Mirror grinding and surface grinding are two different processes used for shaping and finishing flat surfaces, but they differ in their goals and methods. Mirror grinding is a specialized process...

Email to this supplier

August 27, 2024

August 27, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.