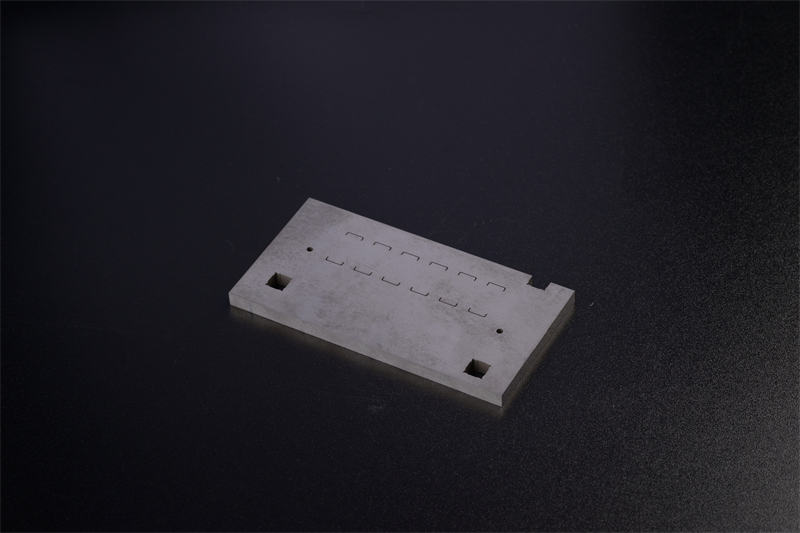

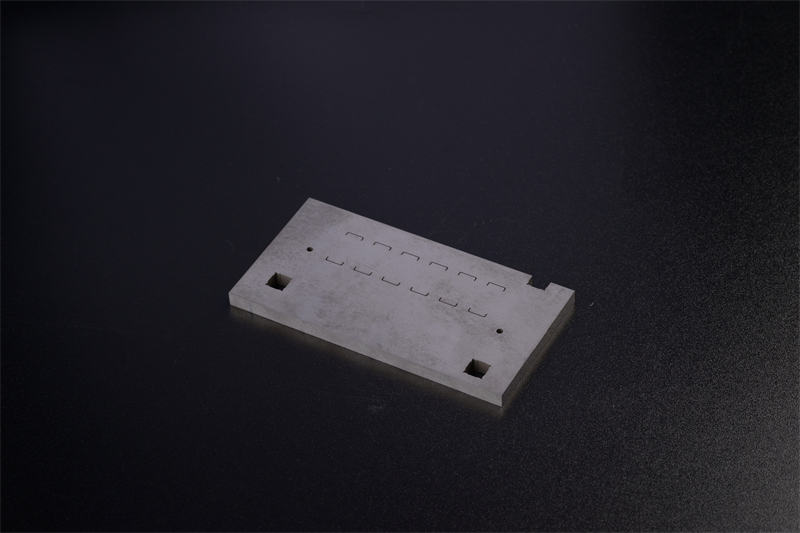

As we all know, open a set of mold weight is hundreds of thousands, light is thousands, it can be said that the cost is quite high, so in the mold manufacturing process, polishing link is particularly important. However, sometimes there will be a slight mistake, it will cause the mold to collapse, may affect the service life of the mold, and will affect the quality of the product, in this case, in order to reduce the loss as much as possible, what measures can be taken to remedy it?

First: Repolish. If the polishing edge is not very serious, you can take the method of re-polishing. Using a fine sandpaper and a grinding head, gently grind the edges until they disappear. It should be noted that re-polishing may change the overall shape of the workpiece, so careful operation is required.

Number two: Fill in the gaps. If the polishing edge is caused by insufficient material or gaps, it can be treated with filling materials. Commonly used filling materials are putty, resin, etc., you can choose the appropriate material to fill according to the specific situation. When filling, it is necessary to pay attention to the curing time and filling depth of the filling material to avoid causing secondary collapse.

Third: Adjust the Angle of the grinding tool. If the polishing edge is caused by improper Angle of the grinding tool, the Angle of the grinding tool can be adjusted. By adjusting the Angle and inclination Angle between the grinding head and the workpiece surface, the grinding force can be reduced to avoid the displacement and deformation of the workpiece.

To sum up, it is necessary to take corresponding measures according to the specific situation to deal with the polishing collapse that has been generated, such as re-polishing, filling gaps, adjusting the Angle of the mold, etc. It should be noted that when dealing with the polishing of the flat edge, the experienced master needs to be patient and careful operation to avoid causing secondary damage or affecting the quality of the workpiece. At the same time, we should also take this as an introduction, as a mold polishing manufacturer, we should strengthen operator training and technical guidance. Only in this way can we ensure the polishing effect and service life of the mold, and improve the quality and competitiveness of the product.