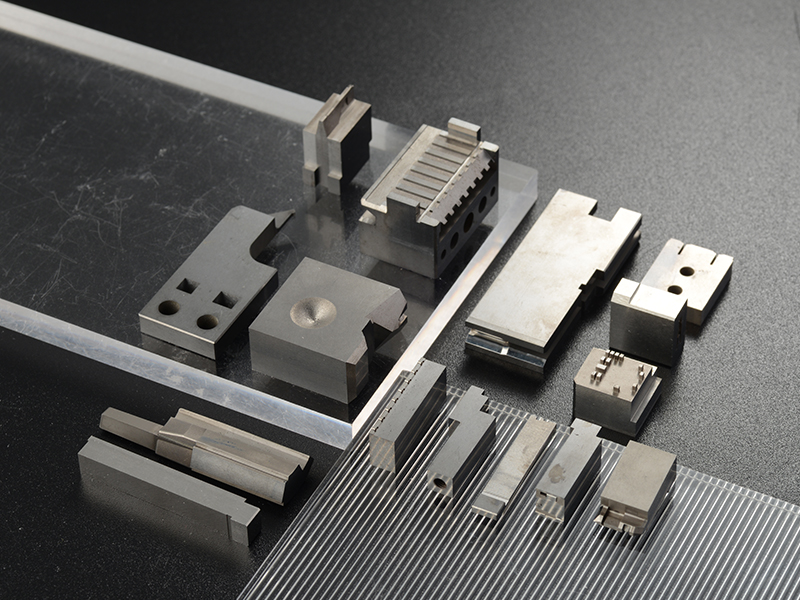

In the manufacturing industry, stamping dies play a crucial role in the production of various metal components and parts. These dies are essential tools designed to shape metal sheets into specific forms with high precision and efficiency. The art and science of creating these intricately designed tools have evolved significantly over the years, leading to the development of various types of stamping dies that cater to different manufacturing needs. Each type of die comes with its unique set of advantages, allowing manufacturers to produce components with tight tolerances and minimal waste. The application range of stamping dies is remarkably broad, encompassing a wide variety of industries from automotive to aerospace.

Types of Stamping Die

Stamping dies are primarily divided into two broad categories: conventional press dies and progressive dies. Conventional press dies are used on a single press station and are designed to work on small to medium quantities of parts. They are suitable for a wide range of applications and are relatively simpler to design and manufacture. Progressive dies, on the other hand, are sophisticated tools that are loaded into a progressive press. They are capable of producing multiple operations in a single stroke and are highly efficient in production of a large number of similar parts. These dies move the workpiece from one station to another along the length of the die until the final part is produced.

Advantages of Stamping Die

The advantages of stamping dies are numerous, making them an indispensable tool in modern manufacturing processes. Firstly, stamping dies offer high precision due to their intricate design and precise dimensions. This precision translates into high-quality finished products that meet stringent standards. Secondly, the use of stamping dies significantly reduces production time and increases productivity. By performing multiple operations in a single step, progressive dies are particularly efficient in producing large quantities of parts. Furthermore, stamping dies reduce the need for manual finishing operations, lowering labor costs and increasing overall production efficiency.

Application Range of Stamping Die

The application range of stamping dies is vast and diverse, covering virtually every sector of the manufacturing industry. In the automotive industry, stamping dies are used to manufacture car bodies, doors, hoods, and various internal and external components. The aerospace industry benefits from the precision and efficiency of stamping dies in producing parts that must withstand extreme conditions while maintaining lightweight characteristics. Home appliances, electronics, medical devices, and even packaging materials are among the numerous products that rely on stamping dies for their production. The versatility of stamping dies enables manufacturers to produce complex shapes and forms with minimal material waste and high production speeds, making them an essential aspect of modern manufacturing processes.

In conclusion, the evolution of stamping dies has revolutionized the way components are manufactured across multiple industries. Their precision, efficiency, and versatility have become fundamental to the modern manufacturing landscape. By understanding the types of stamping dies, their advantages, and their application range, manufacturers can make informed decisions to meet their specific needs and enhance their production capabilities.