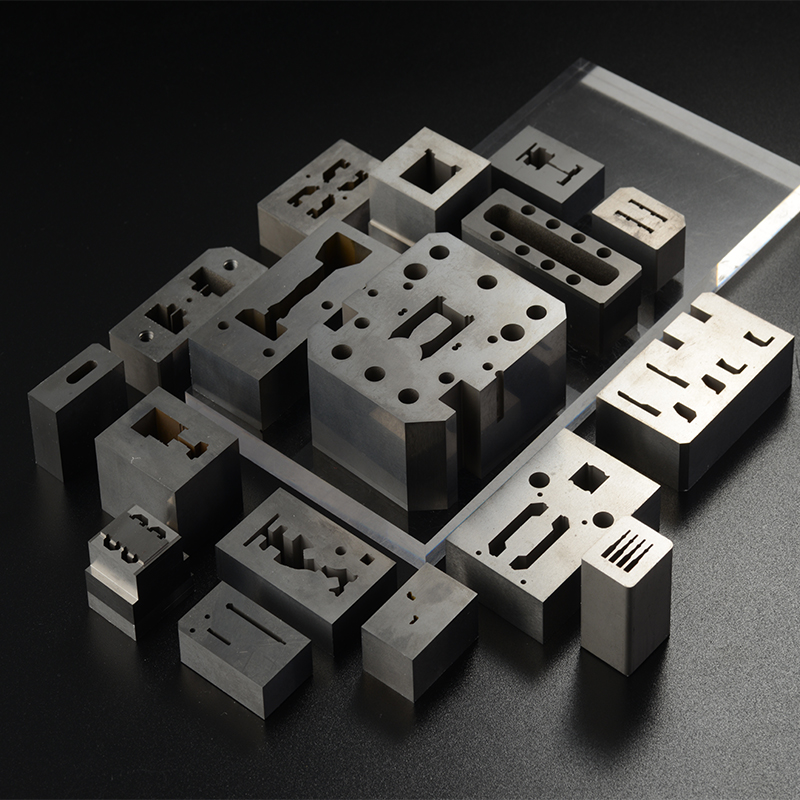

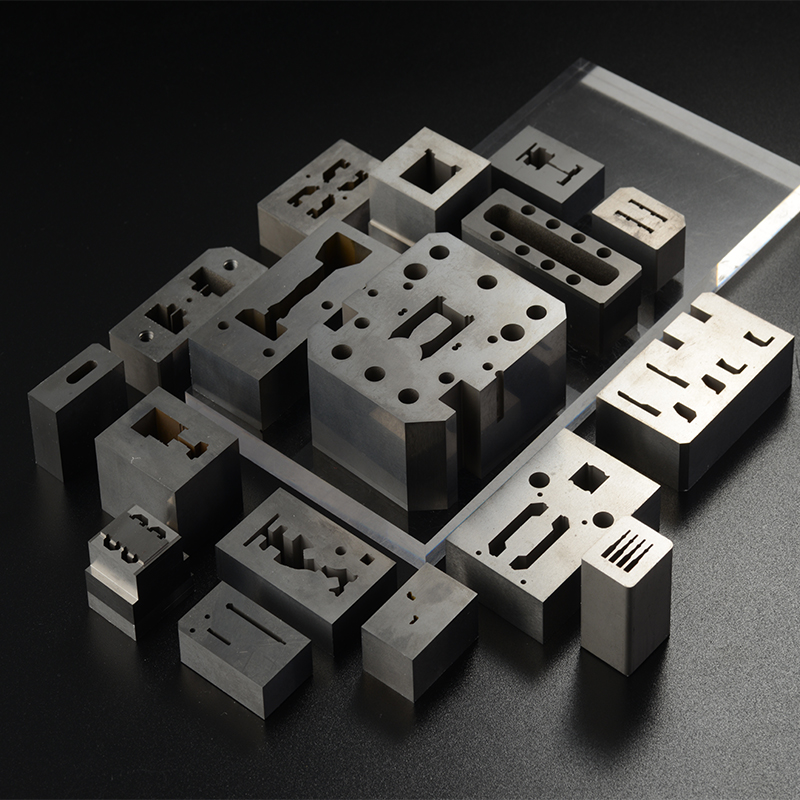

In the realm of manufacturing, precision is a paramount factor that defines the quality and functionality of the final product. When it comes to molds and mold parts, achieving precise dimensions and surface finishes becomes crucial to ensure optimal performance. This is where mold parts precision surface grinding comes into play. It is a process that leverages advanced grinding techniques to achieve high accuracy and exacting tolerances in the production of molds and mold parts. This essay delves into the significance of precision surface grinding and its impact on the manufacturing industry.

Definition and Process Explanation:

Mold parts precision surface grinding is a specialized machining process that employs cutting-edge grinding machines to remove material from the surface of molds and mold parts. It involves the use of abrasive wheels or belts that rotate at high speeds to precisely shave off minuscule amounts of material. This controlled removal ensures uniformity, tight tolerances, and refined surface finishes for the mold parts. The process is meticulously designed to achieve the desired shape, size, and smoothness required for optimal functionality.

Achieving Tight Tolerances:

Precision surface grinding plays a vital role in achieving tight tolerances in mold parts. The process enables manufacturers to create molds and components with dimensions that adhere closely to design specifications, ensuring consistency and accuracy. By eliminating even the slightest deviations, precision surface grinding guarantees the seamless functionality of the molds, resulting in high-quality products. These tight tolerances are particularly crucial in industries such as automotive and aerospace, where precision and reliability are paramount.

Enhancing Surface Finishes:

Proper surface finishes of mold parts are instrumental in the production process. Precision surface grinding enables manufacturers to achieve smooth and polished surfaces, free from imperfections that can compromise the performance of the molds. By meticulously refining the surface texture and removing irregularities, precision surface grinding ensures that molds produce flawless final products. This is especially crucial in industries like medical manufacturing, where the integrity of the mold surface is essential for safety and hygiene purposes.

Impact on Efficiency and Productivity:

Precision surface grinding not only enhances the quality of mold parts but also contributes to improved efficiency and productivity. By utilizing advanced machinery and grinding techniques, manufacturers can expedite the manufacturing process, as well as reduce the need for extensive manual finishing work. This leads to shorter production cycles, increased throughput, and enhanced overall productivity. Additionally, precision surface grinding helps in reducing material waste by precisely removing only the necessary amount of material, supporting sustainability efforts within the manufacturing industry.

Maintenance and Repair:

Apart from the initial manufacturing process, precision surface grinding also plays a pivotal role in the maintenance and repair of molds. Over time, molds may suffer wear and tear or develop surface imperfections. Precision surface grinding allows for the restoration of proper dimensions, surface finishes, and functionality of the molds. By refurbishing and rejuvenating worn-out molds, manufacturers can extend their lifespan and maximize their economic value.

Molds parts precision surface grinding represents a crucial aspect of modern manufacturing. It ensures the attainment of tight tolerances, impeccable surface finishes, and optimal functionality of molds and mold parts. Through this process, manufacturers can surpass the boundaries of precision, resulting in high-quality products across various industries. Precision surface grinding is not only a means of achieving the desired dimensions and finishes but also a catalyst for increased efficiency, productivity, and sustainability within the manufacturing sector. As technology continues to advance, precision surface grinding will continue to evolve, further refining the art of precision and contributing to the growth and success of the industry.