Slow wire is a kind of electrical discharge

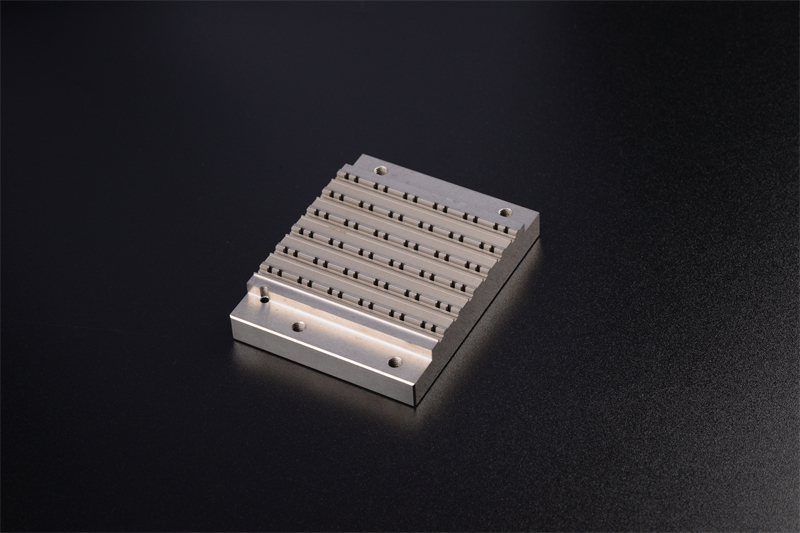

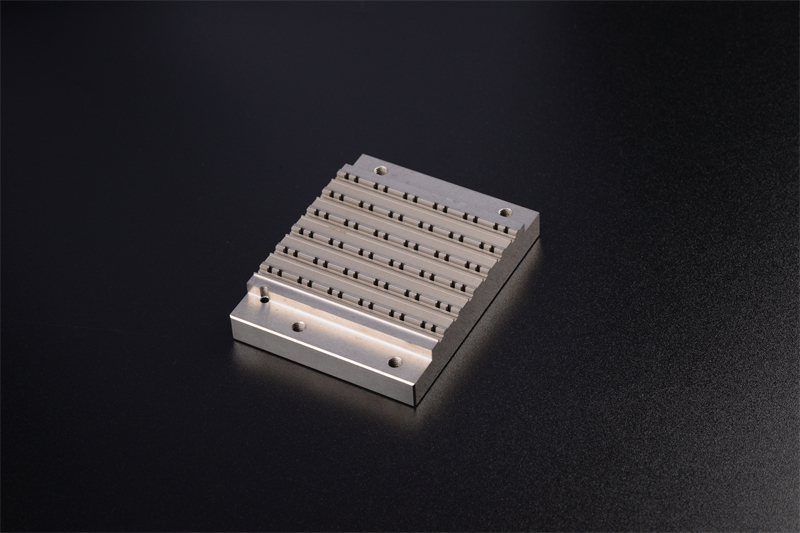

Wire cutting, its abbreviation is (WEDM-LS) is the use of continuous moving thin metal wire (called electrode wire) as an electrode, pulse spark discharge on the workpiece to corrode metal, cutting molding. It is mainly used for processing a variety of complex shapes and precision fine workpieces, according to the electrode wire material is different (one is molybdenum wire, one is copper wire), EDM wire cutting machine is usually divided into two categories: One is slow wire (electrode wire is copper wire) electrode wire for low speed one-way movement, generally the wire speed is less than 0.2m/s, the accuracy is 0.001mm, and the surface quality is close to the grinding level. The electrode wire is no longer used after discharge, and the work is stable, uniform, small jitter, and the processing quality is good. Moreover, advanced power technology enables high-speed machining with a maximum productivity of 350mm2/min.

Electrical discharge wire cutting is referred to as wire cutting. It is developed on the basis of electric spark perforation and forming processing. It has not only developed the application of EDM, but also replaced EDM perforation and forming in some aspects. Today, wire-cut machine tools have accounted for most of the EDM machine tools. The finished surface is rough.

Slow wire processing is also a kind of wire cutting, is the use of continuous moving thin metal wire (called electrode wire) as an electrode, pulse spark discharge on the workpiece to corrode metal, cutting molding. It is mainly used for processing a variety of complex shapes and precision fine workpieces, according to the speed of the electrode wire is different, EDM machine tools are usually divided into two categories: One is the slow wire (also known as low-speed wire EDM machine tool) electrode wire for low-speed one-way movement, generally the wire speed is less than 0.2m/s, the accuracy of 0.001mm, the surface quality is close to the grinding level. The finished surface is very smooth.

Because the slow wire cutting machine adopts the method of continuous wire supply of the wire electrode, that is, the wire electrode is processed in the process of motion, so even if the loss of the wire electrode, it can be continuously supplemented, so it can improve the machining accuracy of the parts. The surface roughness of the workpiece processed by the slow wire cutting machine can usually reach Ra=0.8μm and above, and the roundness error, linear error and dimensional error of the slow wire cutting machine are much faster than the wire cutting machine, so the slow wire cutting machine has been widely used in the processing of high-precision parts. In addition to the early small and medium-sized enterprises, it is also very common in the processing plants of large enterprises such as aviation, automotive, medical and so on.