The superiorities of cemented carbide molds are numerous in the stamping industry, where they find extensive application in manufacturing metal components. Cemented carbide molds are prized for their wear resistance, high hardness, heat resistance, and corrosion resistance. This material is commonly used for making stamping dies due to its high hardness and excellent wear resistance, allowing it to withstand high levels of impact and friction and ensuring a long service life for the molds.

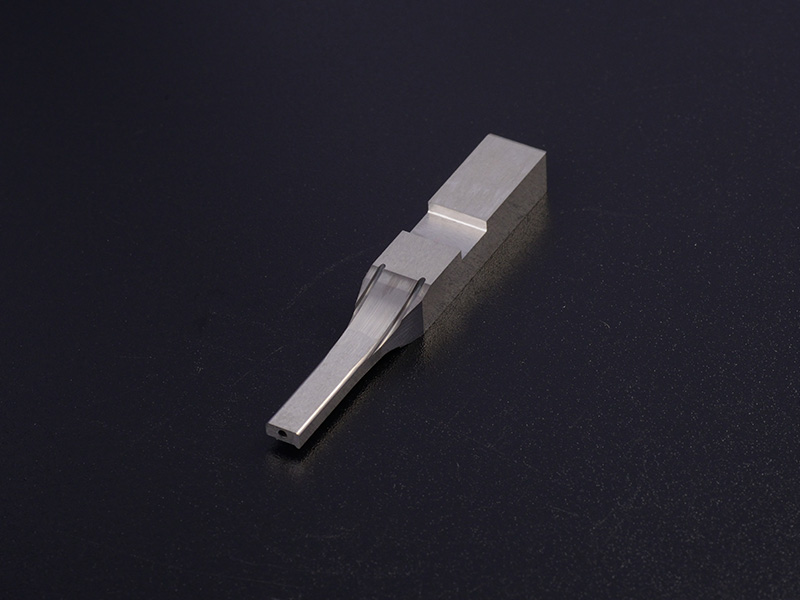

Carbide mold components include cold heading dies, cold punching dies, wire drawing dies, hexagonal dies, and thread rolling dies. Cemented carbide itself offers high hardness, good wear resistance, strength, toughness, heat resistance, and corrosion resistance, thereby endowing molds with a range of excellent properties.

Cemented carbide molds exhibit high wear resistance, ensuring prolonged operation of drawing dies under any deformation conditions and maintaining consistent dimensions of standard parts. They also possess good polishability, capable of producing mirror-like mold cavities, ensuring high-quality external appearance of standard components. Additionally, the high thermal conductivity of cemented carbide quickly dissipates heat generated during cold heading processes, thereby enhancing mold durability.

In the stamping industry, cemented carbide-made components such as punches and pins withstand high levels of impact and pressure during stamping processes, ensuring stability and precision throughout production. Cemented carbide molds play a crucial role in enhancing production efficiency and ensuring product quality, making them indispensable in the stamping industry.

With over a decade of experience specializing in the production, manufacturing, and processing of cemented carbide molds, we offer a comprehensive range of standard and custom mold types. Our company boasts strong capabilities, advanced processing equipment, and rigorous quality assurance, placing us at the forefront of the industry domestically. We are your preferred partner for cemented carbide molds, offering unmatched expertise and reliability.