Unveiling the Precision of PG Optical Curve Grinding for Mold Components

March 22, 2024

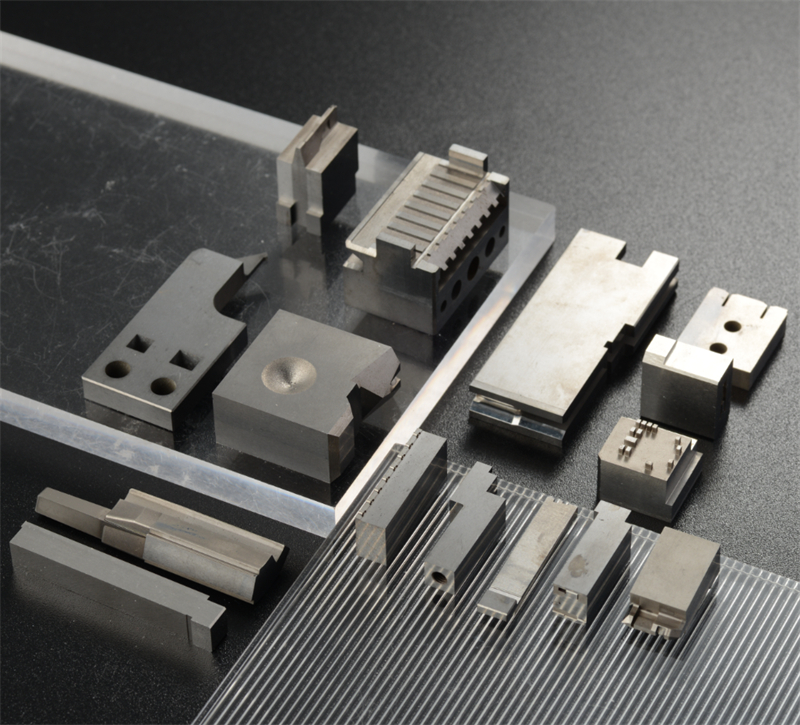

PG Optical Curve Grinding, an advanced machining technique, has been making waves in the manufacturing industry for its ability to produce precision mold components with exceptional accuracy and surface quality. In this article, we delve into the world of PG Optical Curve Grinding and explore its significance in creating high-quality mold components for various industries.

PG Optical Curve Grinding:

PG Optical Curve Grinding is a cutting-edge method that utilizes precision optics and advanced grinding technologies to shape and refine complex curves on mold components. This process involves the use of specialized grinding machines equipped with high-resolution optical systems that allow for ultra-precise control over the machining operations. By leveraging the principles of optics and precision grinding, PG Optical Curve Grinding ensures unparalleled accuracy and repeatability in the production of intricate mold components.

Precision Mold Components:

The application of PG Optical Curve Grinding in manufacturing precision mold components has revolutionized the production of molds for various industries, including automotive, aerospace, and electronics. With the ability to achieve micron-level accuracy and surface finishes, PG Optical Curve Grinding enables the creation of molds with intricate geometries and tight tolerances, essential for producing high-quality end products. Precision mold components manufactured using PG Optical Curve Grinding not only enhance the efficiency of the molding process but also contribute to the overall quality and performance of the final products.

Advantages of PG Optical Curve Grinding:

The adoption of PG Optical Curve Grinding for precision mold components offers a plethora of advantages. Firstly, the process allows for the production of complex curves and shapes with unmatched accuracy, ensuring precise replication of design specifications. Secondly, PG Optical Curve Grinding results in superior surface finishes, minimizing the need for additional finishing operations and reducing production time and costs. Lastly, the high level of repeatability and consistency achieved through PG Optical Curve Grinding guarantees the reliability and durability of the mold components, optimizing the manufacturing process and product quality.

In conclusion, PG Optical Curve Grinding stands as a game-changer in the realm of precision manufacturing, particularly in the production of mold components. The fusion of precision optics and advanced grinding technologies empowers manufacturers to create mold components with exceptional accuracy, surface finish, and repeatability, setting new standards for quality and efficiency. As the demand for high-precision components continues to rise across industries, PG Optical Curve Grinding emerges as a key enabler of innovation and excellence, shaping the future of mold manufacturing in the American industrial landscape.