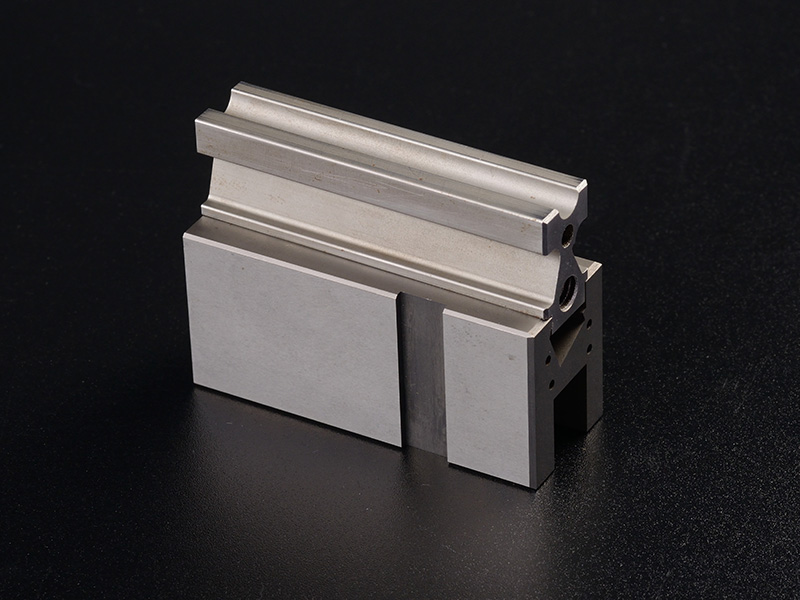

The core components and manufacturing precision of stamping dies are crucial in the metal processing industry. As essential tools, their design and fabrication quality directly impact the accuracy and efficiency of stamped parts. A complete stamping die typically comprises several key parts that work together to ensure a smooth stamping process.

Firstly, the upper and lower dies are the fundamental components of a stamping die. The upper die usually includes a punch and a die plate, used to shape the part’s outer form during stamping. The lower die consists of a die cavity and a bolster plate, supporting the material and withstanding stamping forces to ensure accurate formation of the stamped part as per design requirements.

In addition to the upper and lower dies, guiding components are indispensable in stamping dies. These parts include guide posts, bushings, and guide plates, ensuring precise alignment of the upper and lower dies during closure to avoid misalignment and damage, thereby guaranteeing accuracy in stamped parts.

Custom Metal Stamping Die During the stamping process, to ensure the die’s normal operation and prolong its lifespan, parts for unloading and blank holding are also utilized. Unloading parts, such as an ejector plate, are used to remove parts from the die after stamping; while blank holding parts, like blanking pins, are used to support the material during stamping for subsequent operations.

Furthermore, stamping dies also include various fixed and connecting parts like die handles, retention plates, and screws. These parts ensure tight connections of die components, forming a stable whole, thus facilitating a smooth stamping process.

In summary, the main components of a stamping die include upper and lower dies, guiding parts, unloading and blank holding parts, as well as fixed and connecting parts. These components play crucial roles in the design and fabrication of dies, with their precision and quality directly impacting the quality and production efficiency of stamped parts. Therefore, strict control over the machining precision and assembly quality of each part is essential in manufacturing stamping dies to ensure optimal overall performance.