In modern manufacturing, selecting and using molds is essential for production efficiency, product quality, and cost control. Two common types of molds are hardware molds and stamping molds. They differ significantly in structure, materials, manufacturing processes, and applications.

Hardware Molds

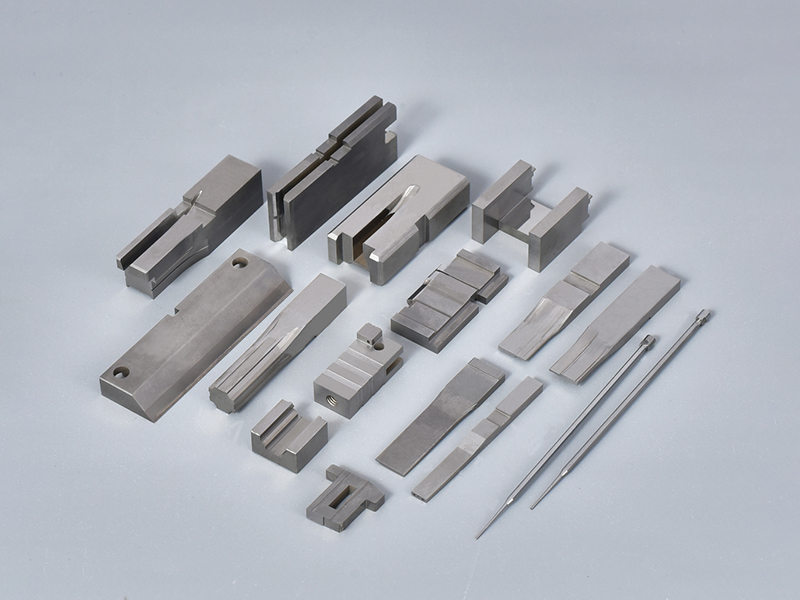

Hardware molds are primarily used to make various metal parts. They create complex shapes through methods like die casting and punching.

Stamping Molds

Stamping molds use pressure to produce thin metal parts. They mainly form parts through stamping and stretching.

Structure and Materials of Hardware and Stamping Molds

Hardware Molds:

The structure of hardware molds includes a mold base, mold body, core, sliding block, ejector pin, and screws. Common materials are high-speed steel, hard alloys, and alloy steel. These materials offer excellent wear resistance and hardness, ensuring long-term stability.

Stamping Molds:

Stamping molds consist of an upper die base, lower die base, blanking plate, cavity die, and punch. They are usually made from hard alloys and tungsten steel. These materials can withstand high pressure and temperature, ensuring precision during the stamping process.

Manufacturing Process of Hardware and Stamping Molds

Hardware Molds Manufacturing Process:

The process for making hardware molds starts with rough machining based on design drawings. This is followed by fine machining using CNC machines and heat treatment of semi-finished products. Heat treatment enhances hardness and wear resistance. Finally, surface treatment is done to improve corrosion resistance.

Stamping Molds Manufacturing Process:

In stamping molds, the design phase must consider pressure transfer, material flow, and part precision. The manufacturing process includes pre-stretching, blanking, and stretching. Large parts may need several steps to ensure performance and precision.

Application Areas of Hardware and Stamping Molds

Hardware Molds:

Hardware molds are widely used in mechanical and automotive manufacturing, as well as in home appliances. They create die casting molds for gears and shafts, and punching molds for parts like pipe fittings and electrical connectors.

Stamping Molds:

Stamping molds are mainly used in automotive manufacturing, electronics, and home appliances. Common applications include stamping large metal sheets for car body panels and frames, as well as precise parts like phone housings and TV backs.

In summary, hardware molds and stamping molds differ significantly in their manufacturing processes and applications. Hardware molds focus on producing various high-precision metal parts with long lifespans, suitable for large-scale production. In contrast, stamping molds are used for thin metal parts, offering high efficiency and lower costs, especially in automotive and appliance sectors. Choosing the right mold type based on production needs is crucial for efficient production and high-quality products.