In the manufacturing industry, metal stamping is a common processing method. For metal stamping processing, the requirement of precision is very important. Next, the small edition of the hardware stamping processing plant will introduce the precision requirements of hardware stamping processing and related details in detail.

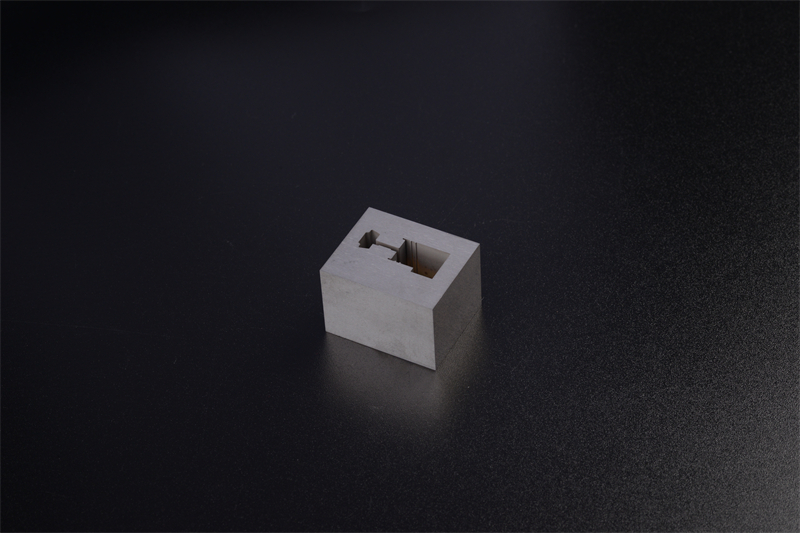

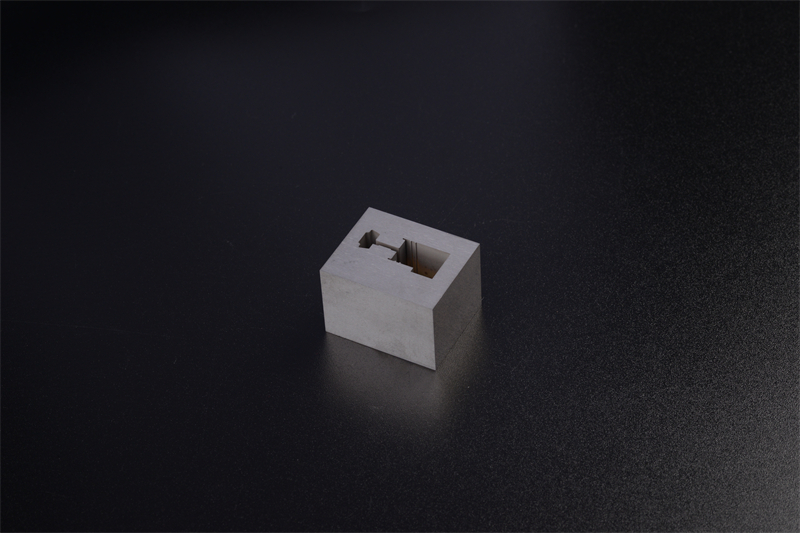

precision metal stamping die processing overview Metal stamping is a technology that processes sheet metal through stamping equipment. It includes cutting, punching, bending and other processes, and can process metal sheets into parts of various shapes. In the manufacturing industry, metal stamping is widely used in electronics, automobiles, home appliances and other fields.

precision metal stamping die processing precision requirements 1. Dimensional accuracy requirements

In metal stamping processing, the dimensional accuracy of parts is very high. Under normal circumstances, the dimensional tolerance is required to be within 0.05mm. This means that the difference between the actual size of the component and the design size should be controlled within the permissible range.

2. Geometric shape accuracy requirements

In addition to dimensional accuracy, metal stamping processing also has certain requirements for the geometric accuracy of parts. This includes requirements for flatness, roundness, verticality and so on. For example, for some parts that need to be chimed with other parts, their flatness and verticality are required to ensure the accuracy of assembly.

3. Surface quality requirements

Parts after metal stamping processing also need to meet certain surface quality requirements. The surface should have no obvious scratches, bumps, bubbles and other defects, and should have a certain finish. This is not only for aesthetics, but also to ensure the function and service life of the parts.

4. Other requirements

In addition to the above basic accuracy requirements, metal stamping processing may also have some special requirements. For example, for some parts that need to be electroplated or sprayed, factors such as the thickness and adhesion of the electroplated or sprayed layer need to be considered.

precision metal stamping processing accuracy assurance measures 1. Reasonable mold design

Die is one of the important factors affecting the precision of metal stamping. Reasonable mold design can ensure that the machined parts meet the required accuracy. Therefore, when designing the mold, it is necessary to fully consider the accuracy requirements of the processing technology and parts.

2. Precision processing equipment

In metal stamping processing, the use of precision processing equipment can improve the accuracy of processing. For example, high-precision punching machines, CNC shearing machines and other equipment can better meet the accuracy requirements, and can ensure stable processing quality.

3. Strict quality control

In the process of metal stamping, strict quality control is the key to ensure accuracy. For each process, it is necessary to carry out strict inspection and control to exclude unqualified products and ensure the precision and quality of processing.

In summary, the precision requirements of metal stamping processing are very high. Dimensional accuracy, geometric shape accuracy, surface quality and other aspects need to be strictly controlled. Through reasonable mold design, precision processing equipment and strict quality control, we can ensure the accuracy of metal stamping processing and meet the needs of customers. The above content is shared with you here, the content is for your reference only! If you want to consult more information about metal stamping processing, please pay attention to the website of Kechuang Metal stamping processing manufacturer (http://www.kcwujin.com/), we will update the relevant content regularly; Stay tuned; If you want to consult the price of metal stamping processing, welcome to inquire!