Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

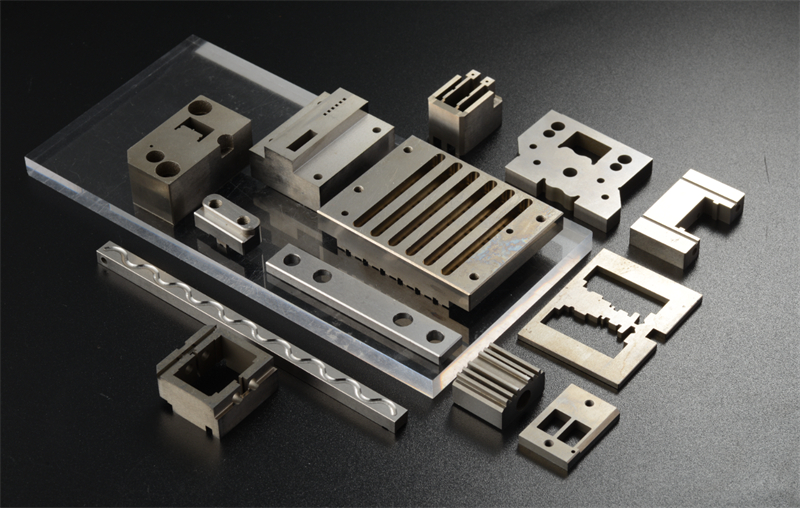

Precision grinding is a critical process employed in various industries, ranging from automotive and aerospace to medical and electronics. It is a highly specialized technique used to improve the surface quality and dimensional accuracy of a workpiece. Achieving the desired finish requires the utilization of advanced grinding methods and processes. Grinding is a material removal process that involves the use of abrasive particles to shape and smooth the surface of a workpiece. The method involves the application of force to the workpiece, causing the abrasive particles to remove tiny chips of material. This process is repeated until the desired surface finish is achieved. Grinding techniques can be classified into different categories, such as surface grinding, cylindrical grinding, and centerless grinding, each suited for specific applications.

What is the grinding method?

Surface grinding is one of the most common grinding methods, widely used for achieving high-quality finishes on flat surfaces. It involves the use of a rotating abrasive wheel to remove material from the workpiece, resulting in a smooth and flat surface. Cylindrical grinding, on the other hand, is employed to create accurate cylindrical shapes or contours. This method utilizes a cylindrical grinding wheel to remove material from the workpiece, achieving precise dimensions and surface finishes. Centerless grinding, a highly efficient technique, is commonly used for grinding cylindrical parts without the need for centers. It involves the use of two wheels: a regulating wheel that controls the rotation speed of the workpiece and a grinding wheel that removes material.

In order to achieve the desired finish, several factors need to be considered during the grinding process. These include the selection of the appropriate grinding wheel, the choice of grinding parameters such as speed, feed rate, and depth of cut, and the use of appropriate cooling or lubrication methods. The grinding wheel's composition and grain size play a crucial role in determining the surface finish and material removal rate. Furthermore, maintaining proper machine rigidity, minimizing vibrations, and ensuring accurate wheel dressing are essential for achieving precise and consistent results. The finish grinding process is not only essential for improving the aesthetics of a workpiece but also plays a crucial role in enhancing its functional performance. Precision grinding techniques enable manufacturers to produce components with superior surface finishes, precise dimensions, and tight tolerances.

August 27, 2024

August 27, 2024

Mirror grinding and surface grinding are two different processes used for shaping and finishing flat surfaces, but they differ in their goals and methods. Mirror grinding is a specialized process...

Email to this supplier

August 27, 2024

August 27, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.