The selection of materials for

Metal Stamping Dies is a crucial step in die manufacturing. Various metal and non-metal materials are used in stamping dies, including carbon steel, alloy steel, cast iron, cast steel, hard alloy, low melting point alloy, zinc-based alloy, aluminum bronze, synthetic resin, polyurethane rubber, plastic, laminated birch plywood, etc. The selection of suitable die materials needs to consider multiple factors, mainly including the hardness, strength, wear resistance, toughness, quenching permeability, and heat treatment stability of the materials.

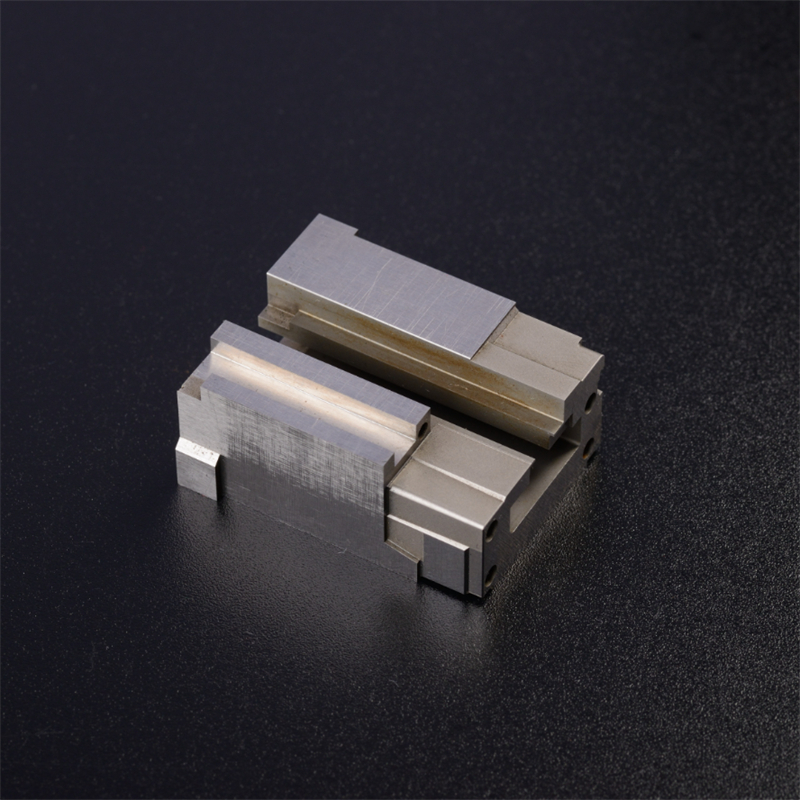

Commonly used die materials include carbon tool steel, low-alloy tool steel, high carbon high chromium tool steel, high carbon medium chromium tool steel, high-speed steel, matrix steel, hard alloy, and steel-bonded hard alloy. Carbon tool steel is widely used in dies due to its good machinability and low cost, but it has poor quenching permeability and red hardness. Low-alloy tool steel is based on carbon tool steel with added alloy elements, which has better quenching permeability and wear resistance. High carbon high chromium tool steel has good quenching permeability, quenching hardness, and wear resistance, with minimal deformation during heat treatment. High-speed steel has the highest hardness, wear resistance, and compressive strength, suitable for high-strength requirement dies. Matrix steel is based on high-speed steel, with high strength, toughness, and fatigue strength, suitable for dies with high wear resistance.

In addition, hard alloy and steel-bonded hard alloy are also widely used in the field of die manufacturing. Hard alloy has high hardness and wear resistance, but poor bending strength and toughness, suitable for high wear resistance dies. Steel-bonded hard alloy is made by adding alloy element powder to iron powder, with the strength of steel and the wear resistance of hard alloy, suitable for dies that require cutting, welding, forging, and heat treatment.

When selecting metal stamping dies materials, factors such as production batch, properties of the stamped material, operating conditions of die components, material properties, reduction of production costs, development of special die steels, and consideration of the production and utilization of domestic dies need to be considered. By considering these factors comprehensively, suitable metal stamping dies materials can be selected to ensure high efficiency, longevity, and production efficiency of the dies.